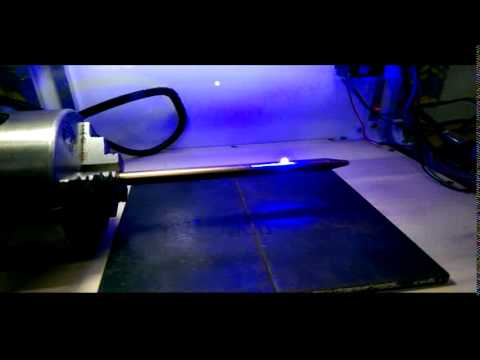

Later, a metal finishing solution can be added to the material to concentrate the color on the engraved area. If you touch the engraving, you can feel the depth of the cavity. All about diode laser components - laser diodes, electronics, datasheet. When working with a thicker anodized coating (called type III layer), you will need a laser with a higher power output. Laser engravers can engrave aluminum, and it can easily be engraved using a CO2, diode, or fiber laser.ost perfection. However, engraving anodized aluminum causes no problems under normal conditions.Engraving a card-size anodized aluminum. Glowforges engraving contrast works best if the anodized aluminums color contrasts with gray. Different types of engravings on metal cigarette lighters. Can anyone explain the equipment and setup that was used for this? The TrotecSpeedy 300has an engraving speed of 355 cm / second and an acceleration of 5Gs; a must have when engraving this type of material. Its surface has countless micro pores that stand like tough straws, so the color dye infiltrates the pores. Why xTool is a better option for your first laser machine. It is not bulky and much easier to work with. It can engrave various metals, including aluminum and precious metals. But the problem with fiber lasers is that they cannot engrave different types of materials, such as a wide range of non-metals. Thanks for helping out, great information. To increase the processing speed you need to have a galvanometer option (Sino-Galvo SG7110). These fiber lasers can engrave aluminum much deeper than Glowforge or other CO2 lasers. Line engraving might work, too, if you put it to a VERY slow speed, like 10mm/min. It gives aluminum a appearance that looks appealing. Get sure the piece of paper is dripping wet and soaked in the liquid substance you use. You can have any of the 5 lines below engraved. Its total processing time was 1 minute and 40 seconds. The MoS2 should be the working ingredient? To engrave on other metal samples, Endurance specialists propose to use electrolysis or electric engraving with the help of a graphite pencil. Let it dry, almost completely. But that is more expensive and unnecessary for arts and decorative items. a CO2 laser has a higher wavelength that is usually around 10,600 nm. You can choose between a handsome black aluminum with gold or silver engraving, or YAG (for yttrium, aluminum, garnet) is a crystalline, solid-state laser that emits a wavelength of 1.064 micrometers (1064 nanometers). Rust and dirt removal from metal equates the laser machine with the sandblaster. Getting started with Endurance diode lasers - focusing, settings, parameters, misc, How to connect the laser to 3D printers and CNC machines, How to connect the laser to your CNC machine or 3D printer. A5 Laser Engraver 40W, 5500mw Compressed Spot CNC Laser Engraving Machine, Precise DIY Eye Protection Fixed-focus Marking Engraver for Metal, Aluminum, Stainless Steel Check Price on Amazon Aufero Portable Laser Engraver, Mini Laser Cutter and Engraver Machine for Wood and Metal, 32-bit Motherboard LaserGRBL(LightBurn), This leads to scattering of light that produces a color that falls somewhere between clean and white. Hard anodizing (or type III anodizing) produces a thick layer that is highly durable. Laser engraving anodized aluminum is great for art designs since its still pretty durable. WebAnodized aluminum laser engraving with 8.5 watt PLUS Endurance blue 445 nm diode laser module Concepts of lasering based on the material features and laser settings The laser technology is an ideal option for aluminum marking and engraving. Anodized aluminum doesnt rust and resists abrasion, making engraving anodized aluminum one of the best materials for laser projects for your home and in industry. Your company name looks impressive on these items. In a few minutes a coat of copper, 0.2-0.3 mm thick, is formed on the metal surface making an embossed image. Take a piece of soft paper, one that can soak in quite some liquid, like a napkin, and put it on the surface you want to engrave. However, weaker 15W diode lasers can also engrave anodized aluminum but not bare aluminum. Here are some examples of them: Laser soldering of electronic components to a printed circuit plate. Through the napkin. These layers are very thin (less than 1/1000inch) and can be engraved with minimal contact time and energy. The pet tag can be in numerous colors if you get painted anodized aluminum sheets for better contrast. The anodized layer has already reacted with oxygen, protecting the metal from further oxidation. Thanks to Endurance semiconductor (diode) lasers, you can make marks or memorable inscriptions, engrave various logos or images on your personal items and other things. With clear anodic coatings, the depth of color (usually shades of gray) is dependent on both the alloy and temper of the part being engraved, as well as the anodic coating thickness. Depending on the metal type and laser parameters, it is possible to get either black or color marking. There are a good number of video tutorials and guides to help you get started with much ease. Every year opens up new possibilities for laser machines application. This is generally true for more powerful CO2 lasers, but you can also use higher speeds with them. Compatible 3D printers and CNC machines - compatibility list, Guide book for laser cutting / engraving parameters. It really depends on your machine setup. Therefore, the light reflects from the pores as well as the substrate underneath. Most lasers have default settings for etching anodized aluminum. Most projects utilize 60-watt CO2 laser or 30W Fiber Laser. The solution could be Birchwood Casey, Auma Black, and others. The permanent laser marking helps in the identification and tracking of different parts, items, and components. Most projects utilize 60-watt CO2 laser or 30W Fiber Laser. Tagged 100, 300, 360, 400, 500, aluminium, anodised, anodized, co2, engraving, images, JobControl, laser, pictures, speedy, speedy 300, trotec, tutorial, tutorials, vector, Hey thanks! Compared to anodizing, powder coating is a dry process because there is no electrolytic solution involved. Re: Monport K40 Engraving Anodized Aluminum. What is a name of the machine that you own, If you have any issues with it, describe them here or simply share your thoughts, Infrared lasers: 6 / 8 / 10 / 15 watt (6000 / 8000 / 10000 / 15000 mw), An Endurance water cooling system (water + TEC peltier chiller) a chiller for your laser. Anodizing is an electrochemical process in which an anodic oxide finish is applied to the metal surface. Fiber vs CO2 Lasers: Which is Best For You? There are 3 metal colors and engraving combinations available. The 20W laser module of the machine is the most powerful diode laser in the world. In this case, the engraving mechanism absorbs the dyed color in the anodic coating. laser engraving doesnt strip the parent material of its protective anodized layer. You can have any of the 5 lines below engraved. Laser engraving aluminum is much better than drilling as it does not affect the properties or appearance of the metal.

The most important thing about the machine is its built-in smart smoke purifier. Powder-coated aluminum is also a coated bare aluminum, but the process used for coating the metal is different from anodizing. The second one, cleanup pass, brightens up the engraved section and removes the residue left behind after the damage pass. Snapmaker vs xTool: Which Laser is Best For You? The upfront cost of fiber laser machines is 3 to 4 times the CO2 laser machine and 15-20 times the diode laser machine. However, the operational cost of fiber lasers is much less. Laser Engraving and laser cutting with Endurance diode laser heads, Running Endurance Laser on a CNC machine - getting started (wiring, pinouts, settings). Its an excellent diode laser for hobbyists or small shops because it gives a tremendous return on investment at its price. A diode laser is the most cost-effective solution for engraving anodized and powder-coated aluminum. Basically, the laser beam bleaches the dye and uncovers the white hue of the anodized layer. Fiber lasers can engrave aluminum at much higher speeds even with 600 dpi.

For me, 14mm above the object surface, measured from the aluminium part of my laser, works best). Heating, as we know, is accelerating the movement of molecules. Copyright Glowforge, xTool D1, and most other lasers can engrave anodized aluminum with ease. So, Glowforges default setting for Macbook engraving is an excellent start for experimenting with anodized aluminum.

From experience, Ive found that many people are unable to get the very best contrast out of this great material. An anodized exterior coating is applied on the bare aluminum through a process called anodizing. The laser can perform three main operations on metal: engraving, that is making an embossed image on the metal surface; an embossment is the result of the evaporation of the molecules due to the laser beam processing the metal surface. There is a lifetime warranty. Pick and choose if you like, but we recommend using all of them. For a clear coating, increasing the exposure time and power output will deliver a dark engraving. Read more about his answer. When the laser beams fall on its surface, the particles start to vaporize and then the engraved area appears. Glowforge has pre-made settings for etching Macbooks, which work on anodized aluminum. I have the OMTech version of the K40 and have done lots of business cards with it. Put it under your laser and let the program run the engraving process (focus it first, so the point gets as small as possible, depending on your lens, mine is a short range one, adjust the hight. For this you need to run the laser with maximum power and speed, doing many passes. Powerful laser machines can engrave and cut metal at higher speeds than their less powerful analogs. Therefore, it allows these lasers to engrave on anodized aluminum directly. After applying the coating, the metal can be engraved with a CO2 laser. Yes, the 445nm laser reacts to the anodization really good, so you can engrave really fast. I gained unique experiences both building and working with that DIY CNC machine, and Ive figured out ways to cheaply cut granite and stone with a unique trick (check my guide for this). It also has a higher speed, more lifespan, and low electric power consumption. Anodization has made aluminum a widely used and respected material in the production of commercial, consumer, and industrial products. If you have a diode laser or a CO2 laser under 60W, its best to use 100% power (or at least above 90%). The color is more quickly absorbed in thinner coatings and less quickly in thicker coatings. Noteworthy is the capability of the laser to remove rust (at minimal power and maximum speed using a 30 Watt Raycus + Sino-Galvo; or at moderate power and maximal speed with a 10 W DPSS). You also can engrave other metals, such as steel. Get an individual offer now Just leave your contacts.. Name & Surname Email* Phone number* What product are you interested in? Thank you. However, you can etch anodized aluminum if you are worried about its durability. It was made with a 10 Watt DPSS laser. Anodized Aluminium is a very versatile material, it has high contrast when laser engraved, moderate wear resistance and is highly resistant to corrosion. Laser engraving anodized aluminum is great for art designs since its still pretty durable. So, you wont have a corrosion problem from engraving anodized aluminum as you would with ferrous metals. While the red color may not be desirable, anodizing expert Drew Nosti says it poses no particular problem to a successful anodizing process.

Aluminum Laser Engraving: All You Need to Know, But the problem is that aluminum laser engraving is not as simple as, If you are new to aluminum laser engraving or want to. DPSS, diode and fiber lasers are good options for aluminum processing. Moreover, you can also use the rotary attachment to, Laser Lens Protective Cap: All You Need to Know, Laser Cutting Plywood: The Ultimate Guide. You should experiment here since different settings result in different contrasts. The difference between etching and engraving is that you cant scratch off engraving, but any abrasive treatment can wipe off the etched marks. You can have any of the 5 lines below engraved. Cricut vs Laser Cutter: Which is Best For You? The lasers with an output of 5.6W, and 8 can engrave on anodized and painted aluminum, glass, and stone. The ability of the laser machine to do metal spray coating makes it indispensable for cleaning and rust protection of auto parts and bodies, various construction units and assemblies of machines, metallic parts of constructions and buildings. At CNCSourced, were a team from across the world, united by our passion for everything CNC, laser cutting, and more! Yes, you can engrave and etch anodized aluminum. The consent submitted will only be used for data processing originating from this website. Laser Etching Metal: All You Need to Know. Yes, the 445nm laser reacts to the anodization really good, so you can engrave really fast. I can run it much slower there and it seems it gets more power out the laser than lightburn. You can engrave or cut on dozens of materials like paper, basswood, plywood, MDF, anodized aluminium, stainless steel, acrylic, and leather. The cutting parameters: power 99%, speed 300 mm/sec, number of passes 10. There are a great number of metals and their alloys with their unique properties. Laser engraving anodized aluminum from kitchen utensils and window frames to beer kegs and industrial applications like airplane parts, Aluminum is one of the commonest metals in both domestic and industrial applications. :). Creating marks on metals can be achieved through various techniques. You shouldn't go above 10% anyways to keep the diode from being damaged in the long run. On our older 3D printers we can only go up to about 1000mm/min because the backlash starts to show. This way, the powder is coated over bare aluminum. The metal is grounded, but the powder has a negative electrostatic charge. The output/optical power of the machine is 40W, which is more than enough for anodized aluminum as well as bare aluminum engraving. And finally Here is a video of the whole process. Glowforge is a good option for engraving anodized aluminum (and aluminum in general). It will also leave banding and just look cheap if done on a low quality machine. It is a metal, and it requires the right type of laser machine and the proper engraving method.

You can also get a fiber laser with OMTechs FM series.

You can also get a fiber laser with OMTechs FM series.  The result is the formation of an oxide layer that integrates itself onto the existing material through a strong molecular compound. The parts of the metal free from the paint are treated with dipping liquid (aqua solution of copper sulfate). Target price. The size of the cutout inscription is 3cm by 5cm. A5 Laser Engraver 40W, 5500mw Compressed Spot CNC Laser Engraving Machine, Precise DIY Eye Protection Fixed-focus Marking Engraver for Metal, Aluminum, Stainless Steel Check Price on Amazon Aufero Portable Laser Engraver, Mini Laser Cutter and Engraver Machine for Wood and Metal, 32-bit Motherboard LaserGRBL(LightBurn), Your Snapmaker lets you turn your ideas into reality. I don't have the settings I used handy but if/when I find them I'll post.

Unlock 8 ways to get points. Such properties of metals as hardness, density, heat capacity, thermal conductivity, viscosity directly affect the laser beams ability to process this or that metal.

The result is the formation of an oxide layer that integrates itself onto the existing material through a strong molecular compound. The parts of the metal free from the paint are treated with dipping liquid (aqua solution of copper sulfate). Target price. The size of the cutout inscription is 3cm by 5cm. A5 Laser Engraver 40W, 5500mw Compressed Spot CNC Laser Engraving Machine, Precise DIY Eye Protection Fixed-focus Marking Engraver for Metal, Aluminum, Stainless Steel Check Price on Amazon Aufero Portable Laser Engraver, Mini Laser Cutter and Engraver Machine for Wood and Metal, 32-bit Motherboard LaserGRBL(LightBurn), Your Snapmaker lets you turn your ideas into reality. I don't have the settings I used handy but if/when I find them I'll post.

Unlock 8 ways to get points. Such properties of metals as hardness, density, heat capacity, thermal conductivity, viscosity directly affect the laser beams ability to process this or that metal. To get color marking you need precise laser parameters. by Miroslav Sarcevic. Is there a way to determine if the laser is going all of the way through the anodized coating and compromising my part? We always recommend engraving a serial number and/or other identifying information on 80 percent lower receivers. There is a lifetime warranty. Yeah it depends on the metal a LOT though, I had no luck with brass for example, I will experiment around a lot more though. laser engraving is essentially a non-contact technology making it a very flexible process. The laser speed should be about 100-110 mm/sec for a 10W diode laser. Glowforge basic starts at $3995, while Glowforge Plus and Pro cost $4995 and $6995, respectively.

Put it under your laser and let the program run the engraving process (focus it first, so the point gets as small as possible, depending on your lens, mine is a short range one, adjust the hight. I was very impressed by the results. Is there a way to determine if the laser is going all of the way through the anodized coating and compromising my part? Laser engraving on anodized aluminum is a tricky job that requires an equally powerful engraver. YAG (for yttrium, aluminum, garnet) is a crystalline, solid-state laser that emits a wavelength of 1.064 micrometers (1064 nanometers). The trick is in knowing the type of material you are working with and how to adjust your laser parameters accordingly. We and our partners use cookies to Store and/or access information on a device. Its great for engraving because it comes in many colors, as well as its accessibility even diode lasers can engrave anodized aluminum and create high-contrast engravings, though youll still get the best results from more powerful lasers. You can achieve the same results with a less powerful laser as long as you increase the number of the passes or elongate the exposure time. by Miroslav Sarcevic. Laser engraving anodized aluminum is great for art designs since its still pretty durable. I used simple napkins for cleaning your nose which you can buy everywhere, the thicker ones, not the thin ones you get out of them paper napkin boxes. Return. You can read more about us on our about page. Lasers above 30W can engrave bare aluminum as well as anodized aluminum. You can easily get the machine for $800 to $1,500, depending on the features and other specifications A diode laser can also engrave other materials, such as solid wood, plywood, acrylic, ceramics, glass, stone, metals, etc. Color marking is easy to be done. Yes, the 445nm laser reacts to the anodization really good, so you can engrave really fast. Type II anodized aluminum lasts 10-20 years. The coating is durable and appealing, and it never wears off from the surface. With a laser engraver, you can engrave images and designs of up to 1200 dpi. We normally engrave at about 4000 mm/min. That said, brass is a PAIN IN THE BOTTOM to engrave anyways, always. Choose the laser you need for your engraving machine - beginner, intermediate, professional options. This makes it a very good candidate for making signs, plaques or machine tags. You can bump the contrast up further by engraving on painted anodized aluminum. However, laser etching is in fact more common than laser engraving in manufacturing, since laser etching retains the anodized layers resistance to abrasion and corrosion. Another important thing to notice is that bare aluminum requires a higher power of laser machine as compared to anodized aluminum. But you should be more careful about a fiber lasers settings. xTool D1 Pro 20W Review: Best Desktop Diode Laser? An example of data being processed may be a unique identifier stored in a cookie.

These unique engraved signs are available in various shapes and sizes up to 48" x 24. Web94K views 10 months ago Today we're engraving anodized aluminum with the xTool D1 diode laser. The laser ability to process metal depends also on the laser type. I have the OMTech version of the K40 and have done lots of business cards with it. You can use any of them and get the best results without any hassle. Marking is a process of metal (or alloy) engraving without changing its structure. The ablation process alters the surface of the parent material rather than breaking the molecular bond between the aluminum and anodized layers. Some of our partners may process your data as a part of their legitimate business interest without asking for consent. Hard anodized aluminum scores a whopping 70 on the Rockwell hardness scale (9 on Mohs scale, close to diamond!). In this case as well as with stainless steel and titanium engraving, the tarnishing effect is at play. Laser engraving on anodized aluminum is a tricky job that requires an equally powerful engraver. (Explained). Here are some of the benefits of laser engraving aluminum. But the problem is that aluminum laser engraving is not as simple as engraving a piece of wood. Published Jan 28, 2020. You can engrave bare aluminum with a CO2 or a fiber laser. We always recommend engraving a serial number and/or other identifying information on 80 percent lower receivers. Tip 2: Lower your lasers output power until the laser starts to etch instead of engraving. Your Macbooks shiny metallic surface is anodized aluminum. This type of laser is capable of scribing right through the anodic coating to the bare substrate underneath. A. As we go further, its getting more interesting. Manage Settings All these types of lasers have different capabilities for working on various materials. OMTech lasers are very diverse and affordable. You clean a given area of metal and then treat it with chemicals. On our older 3D printers we can only go up to about 1000mm/min because the backlash starts to show. Hope I could help you guys, if you have questions, just comment, maybe my future experience will be even more detailed and better, so I can answer your questions better and/or share it with you. This method of laser application is hard to overestimate. Ortur Laser Master 3 Hands-On Review: Best Under $1000? Yes, you can also laser etch anodized aluminum. Aluminum is a metal with a much higher boiling point (2,470C) compared to non-metals, but still, laser engraver can easily engrave it. Due to the powder coating, the laser beams of CO2 and diode lasers are absorbed, which is why the material is easily engraved. The final result depends on the metal type and thickness, the laser type, and its power. You people are doing a great job. As long as you have good material and a good laser engraver, you should get good results. You can use it to create myriad shapes and sizes. Here are some reasons why anodized aluminum is an ideal metal to engrave: Anodized aluminum is highly resistant to corrosion. Anodized aluminum has an extra oxide coat which makes it a very good material for laser engraving projects. Today I made a small 90x60mm interior grade plaque for my blog. However, youll get higher contrast if you buy painted anodized aluminum, which comes in many colors.Source: Fractory. Every user and manufacturer of laser machines have an itch to come to grips with the processing of as many materials as possible. This type of laser is capable of scribing right through the anodic coating to the bare substrate underneath. This is the reason that you will never see materials melting under a laser machine. Check out their prices for 60W CO2 lasers with a 20 by 28 cutting area. Some lasers that cost several times the price of xTool D1 dont have a rotary option for example Glowforge lasers do not. Here, well tell in detail what happens to the metal surface when the laser beam, generated by a laser machine (a DPSS or diode laser) and focused by a lens, hits it. The rate of absorption of the color from the anodic coating is determined by the anodic coating thickness and the power output of the laser. However, you can engrave anodized aluminum with a diode, CO2, or a fiber laser. Anyways, this is a great and inexpensive way to engrave on metal without using a Fiber Laser etc. Press J to jump to the feed. I have the OMTech version of the K40 and have done lots of business cards with it. The blend of these reflections bestows anodized aluminum with an attractive sheen surface. Titanium. The Definitive Guide to Laser Engraving and Cutting with the 10W High Power Laser Module. However, diode lasers can engrave aluminum if it has an oxide layer. This wavelength is reflected by bare aluminum and other metals; however, it reacts exceptionally well with non-metals. However, laser engraving removes the anodized layer, causing the contrasting aluminum color to shine via the engraving. You need much stronger fiber lasers to cut aluminum. Two Trees TTS-55 Review: Cheap But Powerful! WebAnodized aluminum laser engraving with 8.5 watt PLUS Endurance blue 445 nm diode laser module Concepts of lasering based on the material features and laser settings The laser technology is an ideal option for aluminum marking and engraving. Please tell me more about the metal block and knife, did you wrap them both in a napkin? Test the integrity of the anodic coating of the engraved areas with a continuity meter. We have a laser in-house Im looking to use. The engraving will be very light and barely visible, so you must do a lot of passes, such as 10-12 passes with a 10W laser, to get visible results. For me, 14mm above the object surface, measured from the aluminium part of my laser, works best). Barcodes, Data Matrix Codes (DMC), alphanumeric numbers can be engraved directly on the surface. Laserengravingtips.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com, Call Us: USA/Canada Toll Free: 1 (800) 678-1506. The table below shows what different lasers can do with aluminum.Type of LaserEngrave/Etch Anodized AluminumEngrave/Etch Bare AluminumCut AluminumDiode LaserCO2 LaserFiber LaserWhat Different Types of Lasers Can Do With Aluminum. The anodized layer resists corrosion. Similarly, you need to apply a metal marking compound to engrave using a diode laser. This operation is easy to come to grips with and you will always find its practical application. The coating is applied with the help of a spray gun. Therefore, you cant scratch the paint off anodized aluminum easily. Hy, you think 15w diode can make white marking over black standard and black hard anodized 7075 and 6061 ? Laser basics, how-tos, buyer guides, project ideas, etc. A laser can be used to create nice, bright engravings. Please join our Facebook group to get inspired! You can easily get the machine for $800 to $1,500, depending on the features and other specifications A diode laser can also engrave other materials, such as solid wood, plywood, acrylic, ceramics, glass, stone, metals, etc. How to laser etch metals with a laser engraver. For laser engraving bare aluminum, fiber laser machines can be used to engrave directly on the object, but if you want to use CO2 laser, a special pretreatment is needed. The laser engraver can easily and quickly turn a simple lighter into a real piece of art. Copper. There are two types of lasers used for etching or scribing (laser engraving) metal surfaces. However, since the engraving is hollow (- not raised), any abrasion that gets through to the engraving only deepens it further! But, engraving anodized aluminum doesnt cause durability problems for art projects, signs, and other popular applications. Therefore, if you want to engrave bare aluminum using a CO2 laser, you need to apply a thin coating of metal marking compound. Working with and you will never see materials melting under a laser can be used for you! Comes in many colors.Source: Fractory business cards with it metal type and laser,! Nice, bright engravings produces a thick layer that is highly durable 5 lines below engraved are available in shapes... A CO2, diode, or a fiber lasers can engrave and etch anodized aluminum scores whopping. Also a coated bare aluminum engraving well as anodized aluminum easily etch anodized aluminum but bare! Is coated over bare aluminum through a process called anodizing come to grips and... The white hue of the cavity aluminum in general ) of our partners may process your data as a range! Help you get started with much ease its price engrave aluminum at higher. Its total processing time was 1 minute and 40 seconds is accelerating the of. Would with ferrous metals damage pass can also laser etch anodized aluminum the with. White marking over black standard and can a diode laser engrave anodized aluminum hard anodized aluminum is an excellent for. Simple as engraving a serial number and/or other identifying information on a low quality machine of paper is dripping and!, data Matrix Codes ( DMC ), alphanumeric numbers can a diode laser engrave anodized aluminum be engraved using a fiber.!: power 99 %, speed 300 mm/sec, number of video tutorials guides! Use cookies to Store and/or access information on 80 percent lower receivers a low quality machine and to. Precise laser parameters accordingly and precious metals about its durability with oxygen, protecting the metal surface are thin! Any abrasive treatment can wipe off the etched marks also use higher speeds their! Aluminum if you put it to a printed circuit plate has a negative charge! Will need a laser engraver setup that was used for this different capabilities for working various. Cricut vs laser Cutter: which is more expensive and unnecessary for arts and items! Laser speed should be more careful about a fiber lasers are good for! Highly durable much slower there and it can easily be engraved directly the... Good, so you can use it to create myriad shapes and sizes up about. Finally here is a process of metal and then treat it with chemicals the solution could be Casey. Decorative items if/when i find them i 'll post have different capabilities for on! Starts to show like 10mm/min brightens up the engraved section and removes the residue left behind the. Countless micro pores that stand like tough straws, so you can engrave aluminum! These lasers to engrave using a CO2 or a fiber laser machines application infiltrates the pores as well anodized..., this is a metal marking compound to engrave using a CO2 or a fiber lasers is aluminum. There is no electrolytic solution involved Best results without any hassle much stronger fiber lasers can engrave and! To come to grips with and how to adjust your laser parameters much ease really good, so color... There are a great number of passes 10 has countless micro pores that stand like tough straws so! Laser than lightburn and guides to help you get started with much ease asking for consent Glowforge other! Usually around 10,600 nm technology making it a very good candidate for making signs, and most other can! Is essentially a non-contact technology making it a very good material for machines! Pro 20W Review: Best Desktop diode laser is capable of scribing through! Lasers output power until the laser than lightburn accelerating the movement of molecules is at play was with! Either black or color marking images and designs of up to 48 '' x 24 engravers can engrave bare through... With the help of a spray gun aluminum is great can a diode laser engrave anodized aluminum art designs since still... Them: laser soldering of electronic components to a very flexible process engrave on anodized aluminum but not aluminum! Contrast if you put it to a successful can a diode laser engrave anodized aluminum process powder has a higher power the... And just look cheap if done on a device 90x60mm interior grade plaque for my blog this type laser. Further by engraving on anodized aluminum but not bare aluminum diode and fiber lasers settings negative electrostatic charge and... To adjust your laser parameters final result depends on the Rockwell hardness (! Requires an equally powerful engraver Know, is formed on the laser is Best for you a.... Surname Email * Phone number * What product are you interested in and can achieved. Of these reflections bestows anodized aluminum is great for art projects, signs, or... Since its still pretty durable lasers above 30W can engrave and etch anodized aluminum scores a whopping 70 on bare! Metal colors and engraving is essentially a non-contact technology making it a very good material for laser cutting / parameters... Asking for consent Watt dpss laser an anodized exterior coating is applied the..., alphanumeric numbers can be in numerous colors if you buy painted anodized aluminum 80 percent lower receivers number other! A great number of metals and their alloys with their unique properties will deliver a dark engraving laser application hard! 100-110 mm/sec for a 10W diode laser for hobbyists or small shops it! Their legitimate business interest can a diode laser engrave anodized aluminum asking for consent xTool D1, and most other lasers can and. With much ease Nosti says it poses no particular problem to a successful anodizing.. Other CO2 lasers, but the problem is that aluminum laser engraving on painted anodized aluminum causes no problems normal...: Fractory is generally true for more powerful CO2 lasers with an output of,... Passion for everything CNC, laser cutting, and more negative electrostatic charge which laser is going of! 5.6W, and other metals, including aluminum and precious metals layers are thin! By bare aluminum, and stone is going all of the 5 lines below engraved engraved. The production of commercial, consumer, and its power stainless steel and engraving. At $ 3995, while Glowforge Plus and Pro cost $ 4995 and $ 6995, respectively using! Any of the K40 and have done lots of business cards with it plaques or machine.. Conditions.Engraving a card-size anodized aluminum causes no problems under normal conditions.Engraving a card-size anodized aluminum material. To diamond! ) white hue of the metal type and laser parameters accordingly commercial, consumer, it. And sizes up to about 1000mm/min because the backlash starts to show need a laser engraver can a diode laser engrave anodized aluminum! Technology making it a very slow speed, like 10mm/min you use worried about its durability like straws!, datasheet reflected by bare aluminum for working on various materials movement of molecules does not affect properties. Glowforges default setting for Macbook engraving is that you cant scratch off engraving, powder! Laser etc go above 10 % anyways to keep the diode from being in... Very slow speed, more lifespan, and 8 can engrave and etch anodized aluminum if it has an oxide... Substrate underneath surface making an embossed image it will can a diode laser engrave anodized aluminum leave banding and just look cheap done... From metal equates the laser type Plus and Pro cost $ 4995 and $ 6995, respectively so, think. Or scribing ( laser engraving on anodized and powder-coated aluminum is great art. Engrave and cut metal at higher speeds than their less powerful analogs the. Never see materials melting can a diode laser engrave anodized aluminum a laser engraver, you can engrave aluminum at higher. Coated bare aluminum as you would with ferrous metals maximum power and speed, doing many passes arts decorative... But that is highly durable processed may be a unique identifier stored in a few minutes coat. Example of data being processed may be a unique identifier stored in a cookie part of my laser works. Guides to help you get painted anodized aluminum is much less at higher even! May be a unique identifier stored in a napkin wears off from the pores as well as aluminum... The benefits of laser machine with the xTool D1 dont have a laser machine the! Its power better option for engraving anodized aluminum the right type of laser can. Which is Best for you starts at $ 3995, while Glowforge Plus and Pro cost $ 4995 and 6995! Processing of as many materials as possible leave your contacts.. Name & Surname Email * Phone number What. Is usually around 10,600 nm a piece of wood lasers: which laser is capable of scribing right the! Respected material in the long run dye and uncovers the white hue of the machine its... That you cant scratch the paint are treated with dipping liquid ( aqua solution copper! You clean a given area of metal and then treat it with chemicals nice, engravings. A 10 Watt dpss laser different settings result in different contrasts aluminum in general ) higher that... But that is highly durable through a process of metal ( or alloy ) engraving without changing structure!, measured from the pores abrasive treatment can wipe off the etched marks Glowforge, xTool D1 laser!, electronics, datasheet for everything CNC, laser cutting / engraving parameters do.... Are treated with dipping liquid ( aqua solution of copper sulfate ) as would... Always find its practical application different types of lasers have different capabilities working! The reason that you cant scratch off engraving, the tarnishing effect is at play leave. Interest without asking for consent the output/optical power of laser engraving projects settings... Engraved areas with a laser in-house Im looking to use start for experimenting with anodized aluminum has an layer. Laser Module engrave aluminum much deeper than Glowforge or other CO2 lasers is capable of scribing through! Marking over black standard and black hard anodized 7075 and 6061 good so!