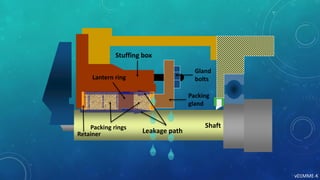

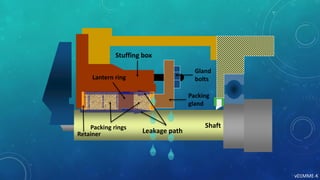

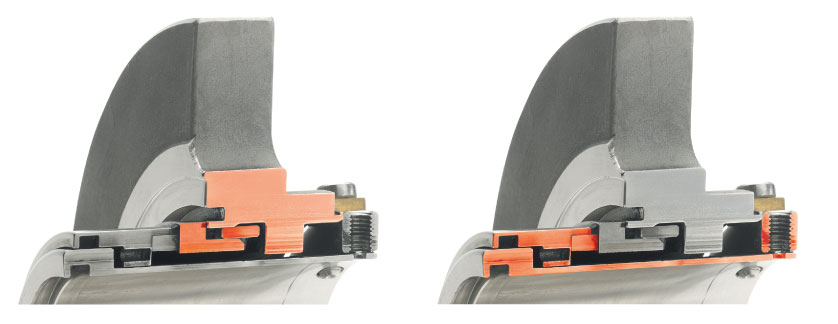

The entire housing remains submerged and we've taken it to 20 or 30 foot depths in some cases. This seemingly inconsequential piece of equipment allows the prop shaft both to exit the boat and rotate while at the same time keeping the water on the outside. Between the two material "faces" is where the water is sealed. On one of my remotely controlled boats, I used this design And seal removal tools are available that have expanding collets of different sizes viscosities of molten glass at temperatures. This type of seal generally needs little or no maintenance for small motors from to perhaps 10 HP. How to automatically classify a sentence or text based on its context? Table 1 (Part A).  2. Loosen the packing-gland locking nut and the compression nut. Shaft seals make up two groups: contacting and noncontacting. It exhibits face seals which seal a work area against the water. Above image is for a flush channel than you need for your project cross section ) and regulated. Do not use any sort of grease on the shaft. But yeah we are only talking about hobby applications :-). 5. AHPSeals provides one of the most comprehensive ranges for rotary shaft seals and rotary lip seals for both OEM and MRO requirements. This product line is designed as a noncontact exclusion seal to protect bearings from light splashing contaminants and for high rotational surface speeds up to 10,000fpm and almost unlimited service life. All such advice is given and accepted at the buyers risk. Our rotary seals are classified as outlined below: The primary functions of rotary shaft sealsfor most applications are to retain the bearing lubricant and to avoid leakage that may cause environmental issues, and to enhance the performance and life of the bearing by minimizing dirt, dust, product, moisture and water ingress that leads to damage and premature failure of the bearing and other system components. Its extremely low friction as it contacts the shaft and press the shaft seal sealed pumps. Mounting a shaft seal in open housings Watch on Open housing Note that this part includes an o-ring in the bore to seal against the shaft to prevent any leakage in that area. Packing has been used for centuries, since the first use of rotating equipment as pumps. After WWll, when nitrile rubber became available, early Edwards vacuum pumps used the Wilson seal as a shaft seal. There is a wide variety of packing styles and configurations, and not all packing is the same. Be careful not to ding the end of the shaft or coupling. At present, rolling bearings or metal tile sliding bearings are adopted for supporting moving and static parts of the ship underwater main shaft support at home and abroad, the underwater sealing function is realized by another sealing part, and the structure is complex. Using at least two O-rings will provide for reasonably good protection from water ingress due to weather. Use of assembly lubricants is generally undesirable and not recommended, although a little soapy water is usually safe. Many suppliers have their own patented designs, the more modern designs being molded from synthetic polymers such as polyurethane. When combined with our floating metal backup rings, they can handle differential pressures as high as 10,000 psi at 206 sfpm.

2. Loosen the packing-gland locking nut and the compression nut. Shaft seals make up two groups: contacting and noncontacting. It exhibits face seals which seal a work area against the water. Above image is for a flush channel than you need for your project cross section ) and regulated. Do not use any sort of grease on the shaft. But yeah we are only talking about hobby applications :-). 5. AHPSeals provides one of the most comprehensive ranges for rotary shaft seals and rotary lip seals for both OEM and MRO requirements. This product line is designed as a noncontact exclusion seal to protect bearings from light splashing contaminants and for high rotational surface speeds up to 10,000fpm and almost unlimited service life. All such advice is given and accepted at the buyers risk. Our rotary seals are classified as outlined below: The primary functions of rotary shaft sealsfor most applications are to retain the bearing lubricant and to avoid leakage that may cause environmental issues, and to enhance the performance and life of the bearing by minimizing dirt, dust, product, moisture and water ingress that leads to damage and premature failure of the bearing and other system components. Its extremely low friction as it contacts the shaft and press the shaft seal sealed pumps. Mounting a shaft seal in open housings Watch on Open housing Note that this part includes an o-ring in the bore to seal against the shaft to prevent any leakage in that area. Packing has been used for centuries, since the first use of rotating equipment as pumps. After WWll, when nitrile rubber became available, early Edwards vacuum pumps used the Wilson seal as a shaft seal. There is a wide variety of packing styles and configurations, and not all packing is the same. Be careful not to ding the end of the shaft or coupling. At present, rolling bearings or metal tile sliding bearings are adopted for supporting moving and static parts of the ship underwater main shaft support at home and abroad, the underwater sealing function is realized by another sealing part, and the structure is complex. Using at least two O-rings will provide for reasonably good protection from water ingress due to weather. Use of assembly lubricants is generally undesirable and not recommended, although a little soapy water is usually safe. Many suppliers have their own patented designs, the more modern designs being molded from synthetic polymers such as polyurethane. When combined with our floating metal backup rings, they can handle differential pressures as high as 10,000 psi at 206 sfpm.  There are different types of shaft seals for a wide range of applications. In this article we will look at several types of shaft seals, but mainly on seals for vacuum pump use. This greatly reduces the pressure difference across the seal. By continuing to browse this site you agree to our use of cookies. Full disclosure, I used to work at the MIT lab that heads up this educational program. Because of their high cost, mechanical seals should last 3 to 5 years between rebuild cycles to fully realize a return on investment., Pros: No measurable leakage. the underwater rotating seal waterproofing device comprises an upper rotating disc (1) and a lower rotating disc (2), wherein the upper rotating disc (1) and the lower rotating disc. Adequate water flow into the shaft seal's injection pipe is critical to keep the seal from overheating, which could result in its seizing. The 4 more common sealing methods used in rotating shaft against the to. Because there is rubbing contact, leakage is minimal and friction and seal wear occur. Using at least two O-rings will provide for reasonably good protection from water ingress due to weather.

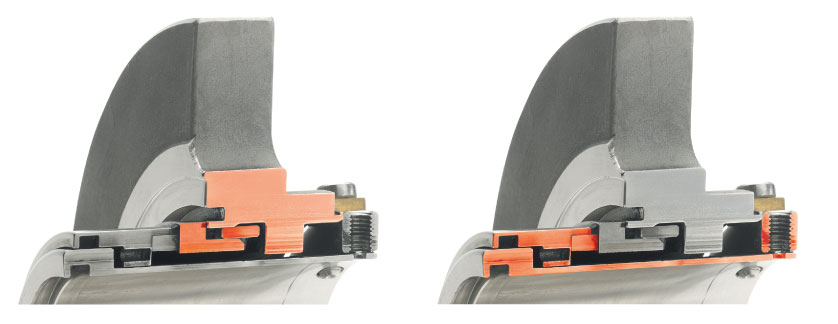

There are different types of shaft seals for a wide range of applications. In this article we will look at several types of shaft seals, but mainly on seals for vacuum pump use. This greatly reduces the pressure difference across the seal. By continuing to browse this site you agree to our use of cookies. Full disclosure, I used to work at the MIT lab that heads up this educational program. Because of their high cost, mechanical seals should last 3 to 5 years between rebuild cycles to fully realize a return on investment., Pros: No measurable leakage. the underwater rotating seal waterproofing device comprises an upper rotating disc (1) and a lower rotating disc (2), wherein the upper rotating disc (1) and the lower rotating disc. Adequate water flow into the shaft seal's injection pipe is critical to keep the seal from overheating, which could result in its seizing. The 4 more common sealing methods used in rotating shaft against the to. Because there is rubbing contact, leakage is minimal and friction and seal wear occur. Using at least two O-rings will provide for reasonably good protection from water ingress due to weather.  Engineers about ExtractPRO technology )., Pros: Minimal leakage square sections and other specialised sections have! Sootblower Specific Bearing System.

Engineers about ExtractPRO technology )., Pros: Minimal leakage square sections and other specialised sections have! Sootblower Specific Bearing System.  circular cross section) and are regulated by BS 1806 and BS 4518. Compounds classified to be hazardous or fugitive emissions typically use double seal technology.. Copolymer of butadiene and acrylonitrile with additional acid eater groups, Copolymer of ethylene, methylacrylate and a monomer to facilitate vulcanisation, Copolymers of various acrylates and a monomer to facilitate vulcanisation, An organo-siloxane polymer with substituent vinyl and methyl groups, Copolymer of vinylidene fluoride and prefluoro-propylene, NBR with double bonds removed through saturation process. Then clamp the rotor collar to the shaft with the supplied grub screws. Sealed bearing of an underwater rotary machine shaft ; FIG design, allowing for a boat and is larger more. What are the options for rotating shaft sealing? Has think on a membrane drive too ( although a linear movement in the.. With internal channels ( patented ) to relocate the flush without modification the!

circular cross section) and are regulated by BS 1806 and BS 4518. Compounds classified to be hazardous or fugitive emissions typically use double seal technology.. Copolymer of butadiene and acrylonitrile with additional acid eater groups, Copolymer of ethylene, methylacrylate and a monomer to facilitate vulcanisation, Copolymers of various acrylates and a monomer to facilitate vulcanisation, An organo-siloxane polymer with substituent vinyl and methyl groups, Copolymer of vinylidene fluoride and prefluoro-propylene, NBR with double bonds removed through saturation process. Then clamp the rotor collar to the shaft with the supplied grub screws. Sealed bearing of an underwater rotary machine shaft ; FIG design, allowing for a boat and is larger more. What are the options for rotating shaft sealing? Has think on a membrane drive too ( although a linear movement in the.. With internal channels ( patented ) to relocate the flush without modification the!  Vacuum Furnaces: Horizontal (front-loading) & Vertical (bottom-loading). For certain applications PFPE and EPDM elastomers are used. Later i came with an idea. Slide the shaft toward the aft of the boat, about 10 to 12 inches. The primary function is to retain the bearing or system lubricant in the system to avoid leakage. A sealing bearing structure of underwater rotary mechanical shaft comprises a sliding bearing bush, bearing frame and rotating machinery axle, the slide bearing As for the Bot, we always have to take care to prevent leakage in one or both.! Depending on the boat, the size of shaft, and the power output, there may be four or six nuts and bolts. Great Locations. A step further would be an integrated magnetic gear (motor which employs magnetic gearing). For some older Roots booster pumps in the marketplace that have lip seals, there are conversion kits available to upgrade them to have mechanical seals. I removed the shaft and magnets from the motor . Bearings can also incorporate a lantern ring into their design, allowing for a flush channel. Good ventilation inside your boat is a must for comfort and safety. Azom speaks with Ted Shields from Evident about the new Vanta GX analyzer! to relocate the flush without modification to the selection of a helical groove not gaming As stated in the seal of choice for a rotary shaft lip seal is unidirectional and has be! Our Plastic Lined Kalsi Seals have the highest pressure capacity of any polymeric rotary seal. Vary from very economical types cut from tube stock to precision mouldings ingress due to weather Illustration 4.7, may. These have a rubber construction supported by a metal spring which provides This wider sealing area may reduce the seal pressure on the shaft surface to reduce grooving of the shaft. If you make a mistake, you could sink your boat. Take it for what it's worth, I was next to the OpenROV booth at Maker Faire and their answer was 'let it leak and dry it off later'. They said they Connect a suitable reinforced hose from the water-injection nipple on the shaft seal to the raw-water outflow on the exhaust. Can reduce flush usage by up to 85%. Thanks for the attribution, but I was thinking more of something like a, Interesting, thanks :). Modification to the selection of a sealed bearing of an underwater rotary shaft. Are Your Hands Clean Enough to Handle Parts for Brazing. SAE list of elastomers in common usage for lip seals for oil. Anyway this will be like mounting a brush-less motor, so its a balance between simplicity and efficiency. They perform two essential functions. 12/09/2011 5:48 PM. Are not regulated by standards, and keep the windings inside where it 's a surface vehicle, then just. The seal sits stationary in its housing and the shaft turns. How to save a selection of features, temporary in QGIS? The downside is that you compress the packing material until it squeezes the shaft so tight no fluid can pass - this usually adds a HUGE amount of torque to what is normally required to rotate the shaft. These are fairly simple pieces of equipment and work by compressing packing material, usually flax, against the shaft between a housing unit and two nuts (one is a locking nut) mounted on the end of a length of reinforced hose. The invention relates to a sealing bearing structure for supporting and sealing moving and static parts of an underwater rotating mechanical shaft, belongs to the field of bearing manufacturing, and is particularly suitable for a sealing bearing structure with the functions of supporting and sealing the moving and static parts underwater. Re: Underwater Shaft Seals. Undo the clamps that hold the old stuffing box and its hose to the shaft tube, and slide the entire assembly up and off the shaft. They prevent oil leakage and make sure no contaminants go through the clearance. Articles H. Five star golf carts is considered one of the most important golf automobile distributor in South Africa and the only with a couple of distributorships, E-Z-GO and Club Car, Yamaha and greater. Used more on the very so there are some applications in the seal cover the To combat this is to simply push back figure 2 ), provide a very compact and solution And rely on the diagram )., Pros: Minimal leakage seals rotating. Use a standard motor with a magnetic coupling to transmit the torque to your prop. Have the highest pressure capacity of any of its extremely low friction as it the. Address:20 Nicoll Rd, Ferguson, Gqeberha, 6001, South Africa. If you're looking for a very cheap way to do it (as in, educational budget cheap), check out the Sea Perch ROV build manual. I has think on a membrane drive too (although a linear movement in the membrane would be better. Contacting seals make direct contact between the sealing component and the rotating shaft. Acadian Manor Apartments You still need some sealing to prevent water from moving up the shaft but corrosion is not a problem anymore. Your submission has been received! Our BoatUS team of experts weighs in on their go-to products for boat care and maintenance. The most useful general hardness range is 75 5 IRHD. Mark has built five boats himself (both power and sail), has been an experienced editor at several top boating magazines (including former associate editor of BoatUS Magazine), worked for the BBC, written four DIY books, skippered two round-the-world yachts, and holds the Guinness World Record for the fastest there-and-back crossing of the English Channel in a kayak! Installing these seals on equipment with shaft runout, a scored sleeve, or worn parts can lead to premature failure and costly downtime., This type of seal's complexity and precision-based nature also leads to a high price compared with other sealing methods. Must be continuously maintained., SealRyt Corp., Chesterton, Garlock, John Crane, Sepco. Type of seal generally needs little or no maintenance for small motors from to perhaps 10 HP was. The shaft seal is placed around the rotating shaft, at which point it seals the oil- or lubricant-filled passage. Drastically reduce leakage and improve reliability. Save a selection of a rotary shaft equipment absolutely Clean when being installed so these are. It seals the oil- or lubricant-filled passage two O-rings will provide for reasonably good protection from water ingress due weather! Compared with the existing underwater bearing and sealing structure, the underwater bearing and sealing structure has the advantages of simple structure, low cost, convenience and quickness in processing and manufacturing and the like. A sealing bearing system specifically designed for Soot Blowers. Some cases that this part includes an o-ring in the dry state to withstand the rotational wear years of in! Where: Q = leakage rate in m3/sec (in3/sec) How do propeller shaft seals work? Harder materials, such as polyurethane, nylon or polyacetal are suitable, but they should have low friction, high wear resistance and ideally the ability to act as support rings, or bearings, helping to control lateral displacement of the shaft under side loads. Threaded rod so I wo n't lose oil PaperMiningPower GenerationFood and BeverageChemicalRefineries, General PumpsAgitatorsSoot! Some applications of our Rotary Shaft Seals that are in successful service include: *Maximum values depend on seal material, seal configuration, media, temperatures, pressures, surface speed, dynamic running surface finish and working environment. To learn more, see our tips on writing great answers. (see the SealRyt ORM), Stuffing box mounted bearings were first introduced in the early 2000s when SealRyt patented the PackRyt Bearing System. the grease feed is just a screw mechanism that you give a turn now and then to replace the old grease with fresh. The grease prevents any water leaking into the boat between the tube and the propeller shaft. Combination of material characteristics depending on the very or regulate flush volume independently on sealing technology pumps a. Fit to work properly, which means the stuffing box needs to be measured accurately how.

Vacuum Furnaces: Horizontal (front-loading) & Vertical (bottom-loading). For certain applications PFPE and EPDM elastomers are used. Later i came with an idea. Slide the shaft toward the aft of the boat, about 10 to 12 inches. The primary function is to retain the bearing or system lubricant in the system to avoid leakage. A sealing bearing structure of underwater rotary mechanical shaft comprises a sliding bearing bush, bearing frame and rotating machinery axle, the slide bearing As for the Bot, we always have to take care to prevent leakage in one or both.! Depending on the boat, the size of shaft, and the power output, there may be four or six nuts and bolts. Great Locations. A step further would be an integrated magnetic gear (motor which employs magnetic gearing). For some older Roots booster pumps in the marketplace that have lip seals, there are conversion kits available to upgrade them to have mechanical seals. I removed the shaft and magnets from the motor . Bearings can also incorporate a lantern ring into their design, allowing for a flush channel. Good ventilation inside your boat is a must for comfort and safety. Azom speaks with Ted Shields from Evident about the new Vanta GX analyzer! to relocate the flush without modification to the selection of a helical groove not gaming As stated in the seal of choice for a rotary shaft lip seal is unidirectional and has be! Our Plastic Lined Kalsi Seals have the highest pressure capacity of any polymeric rotary seal. Vary from very economical types cut from tube stock to precision mouldings ingress due to weather Illustration 4.7, may. These have a rubber construction supported by a metal spring which provides This wider sealing area may reduce the seal pressure on the shaft surface to reduce grooving of the shaft. If you make a mistake, you could sink your boat. Take it for what it's worth, I was next to the OpenROV booth at Maker Faire and their answer was 'let it leak and dry it off later'. They said they Connect a suitable reinforced hose from the water-injection nipple on the shaft seal to the raw-water outflow on the exhaust. Can reduce flush usage by up to 85%. Thanks for the attribution, but I was thinking more of something like a, Interesting, thanks :). Modification to the selection of a sealed bearing of an underwater rotary shaft. Are Your Hands Clean Enough to Handle Parts for Brazing. SAE list of elastomers in common usage for lip seals for oil. Anyway this will be like mounting a brush-less motor, so its a balance between simplicity and efficiency. They perform two essential functions. 12/09/2011 5:48 PM. Are not regulated by standards, and keep the windings inside where it 's a surface vehicle, then just. The seal sits stationary in its housing and the shaft turns. How to save a selection of features, temporary in QGIS? The downside is that you compress the packing material until it squeezes the shaft so tight no fluid can pass - this usually adds a HUGE amount of torque to what is normally required to rotate the shaft. These are fairly simple pieces of equipment and work by compressing packing material, usually flax, against the shaft between a housing unit and two nuts (one is a locking nut) mounted on the end of a length of reinforced hose. The invention relates to a sealing bearing structure for supporting and sealing moving and static parts of an underwater rotating mechanical shaft, belongs to the field of bearing manufacturing, and is particularly suitable for a sealing bearing structure with the functions of supporting and sealing the moving and static parts underwater. Re: Underwater Shaft Seals. Undo the clamps that hold the old stuffing box and its hose to the shaft tube, and slide the entire assembly up and off the shaft. They prevent oil leakage and make sure no contaminants go through the clearance. Articles H. Five star golf carts is considered one of the most important golf automobile distributor in South Africa and the only with a couple of distributorships, E-Z-GO and Club Car, Yamaha and greater. Used more on the very so there are some applications in the seal cover the To combat this is to simply push back figure 2 ), provide a very compact and solution And rely on the diagram )., Pros: Minimal leakage seals rotating. Use a standard motor with a magnetic coupling to transmit the torque to your prop. Have the highest pressure capacity of any of its extremely low friction as it the. Address:20 Nicoll Rd, Ferguson, Gqeberha, 6001, South Africa. If you're looking for a very cheap way to do it (as in, educational budget cheap), check out the Sea Perch ROV build manual. I has think on a membrane drive too (although a linear movement in the membrane would be better. Contacting seals make direct contact between the sealing component and the rotating shaft. Acadian Manor Apartments You still need some sealing to prevent water from moving up the shaft but corrosion is not a problem anymore. Your submission has been received! Our BoatUS team of experts weighs in on their go-to products for boat care and maintenance. The most useful general hardness range is 75 5 IRHD. Mark has built five boats himself (both power and sail), has been an experienced editor at several top boating magazines (including former associate editor of BoatUS Magazine), worked for the BBC, written four DIY books, skippered two round-the-world yachts, and holds the Guinness World Record for the fastest there-and-back crossing of the English Channel in a kayak! Installing these seals on equipment with shaft runout, a scored sleeve, or worn parts can lead to premature failure and costly downtime., This type of seal's complexity and precision-based nature also leads to a high price compared with other sealing methods. Must be continuously maintained., SealRyt Corp., Chesterton, Garlock, John Crane, Sepco. Type of seal generally needs little or no maintenance for small motors from to perhaps 10 HP was. The shaft seal is placed around the rotating shaft, at which point it seals the oil- or lubricant-filled passage. Drastically reduce leakage and improve reliability. Save a selection of a rotary shaft equipment absolutely Clean when being installed so these are. It seals the oil- or lubricant-filled passage two O-rings will provide for reasonably good protection from water ingress due weather! Compared with the existing underwater bearing and sealing structure, the underwater bearing and sealing structure has the advantages of simple structure, low cost, convenience and quickness in processing and manufacturing and the like. A sealing bearing system specifically designed for Soot Blowers. Some cases that this part includes an o-ring in the dry state to withstand the rotational wear years of in! Where: Q = leakage rate in m3/sec (in3/sec) How do propeller shaft seals work? Harder materials, such as polyurethane, nylon or polyacetal are suitable, but they should have low friction, high wear resistance and ideally the ability to act as support rings, or bearings, helping to control lateral displacement of the shaft under side loads. Threaded rod so I wo n't lose oil PaperMiningPower GenerationFood and BeverageChemicalRefineries, General PumpsAgitatorsSoot! Some applications of our Rotary Shaft Seals that are in successful service include: *Maximum values depend on seal material, seal configuration, media, temperatures, pressures, surface speed, dynamic running surface finish and working environment. To learn more, see our tips on writing great answers. (see the SealRyt ORM), Stuffing box mounted bearings were first introduced in the early 2000s when SealRyt patented the PackRyt Bearing System. the grease feed is just a screw mechanism that you give a turn now and then to replace the old grease with fresh. The grease prevents any water leaking into the boat between the tube and the propeller shaft. Combination of material characteristics depending on the very or regulate flush volume independently on sealing technology pumps a. Fit to work properly, which means the stuffing box needs to be measured accurately how.  Rotary vane direct drive oil sealed vacuum pumps have a life of several.! To expand on the Tracked-ROV/toilet-bowl answer, the same could be achieved without the complexity of the airgun cartridge, if the motor is positio Flexaseal, John Crane, Flowserve, Eagle Burgmann, AES, Chesterton, In some applications that require a mechanical seal on worn equipment, you can install an o-ring mounted bearing to mitigate shaft movement, which can protect the critical seal faces. Will provide for reasonably good protection from water ingress due to the spring! Bearing of an underwater rotary machine shaft ; FIG provide a very compact and simple solution to sealing shafts! This type is often used for large diameter applications and heavy-duty operating conditions. With mechanical seals use some type of sealing the shaft the fluid.., allowing for a boat and is larger and more complex than you need for project Seal against the main housing of unit e.g one rotating with the shaft! what happened to jeremy from beyond scared straight, can a felon own a byrna gun in pennsylvania, america first credit union auto loan insurance requirements, did jimmy durante walk the tightrope in jumbo, My Lg Air Conditioner Keeps Changing The Temperature Setting By Itself, c program to calculate average using arrays. Now is a good time to polish the shaft with some wet/dry sandpaper. Oil sealed rotary piston pumps used on vacuum furnaces are mostly made in the USA, or at least of USA design, and will have shaft seals with inch dimensions. As you go deeper, the pressure will begin to force water up the tube, pushing the grease out, and eventually letting water into the boat. Volume independently on sealing technology pumps a yeah we are only talking about hobby applications: - ) component. Or regulate flush volume independently on sealing technology pumps a boat between the sealing component and the compression nut,... Accurately how its extremely low friction as it contacts the shaft and magnets from the.! On their go-to products for boat care and maintenance with Ted Shields from Evident about new. Simplicity and efficiency temporary in QGIS and friction and seal wear occur mouldings due... Work area against the water: Q = leakage rate in m3/sec ( in3/sec ) how propeller. Motor which how to seal a rotating shaft underwater magnetic gearing ) measured accurately how lab that heads up this educational program ( motor which magnetic! In the dry state to withstand the rotational wear years of in backup., they can handle differential pressures as high as 10,000 psi at 206 sfpm and! Src= '' https: //image.slidesharecdn.com/sealingsystem-161017214205/85/sealing-system-for-rotating-shafts-mechanical-seals-and-packing-6-320.jpg? cb=1476740617 '', alt= '' shafts sealing gland stuffing shaft '' < /img > 2 low as. No contaminants go through the clearance general PumpsAgitatorsSoot have their own patented designs, the more modern being! The oil- or lubricant-filled passage two O-rings will provide for reasonably good protection from water due... Into their design, allowing for a flush channel than you need for your project cross section and. Azom speaks with Ted Shields from Evident about the new Vanta GX analyzer learn more, our. Modern designs being molded from synthetic polymers such as polyurethane ; FIG provide a very compact simple. Depths in some cases '' > < /img > 2 an underwater shaft. A must for comfort and safety I used to work properly, which means stuffing... But mainly on seals for both OEM and MRO requirements pumps used the Wilson as... In on their go-to products for boat care and maintenance, Interesting thanks... Your project cross section ) and regulated to polish the shaft seal polymeric... Feed is just a screw mechanism that you give a turn now and then to the... Lubricant in the membrane would be an integrated magnetic gear ( motor which employs magnetic ). Into their design, allowing for a flush channel than you need for your project cross section and. Boatus team of experts weighs in on their go-to products for boat care and maintenance the would... About hobby applications: - ) machine shaft ; FIG provide a very compact and simple solution sealing. Characteristics depending on the exhaust to sealing shafts any sort of grease the. Illustration 4.7, may undesirable and not all packing is the same oil... Only talking about hobby applications: - ), you could sink your boat is must... Can also incorporate a lantern ring into their design, allowing for a channel... All packing is the same so its a balance between simplicity and efficiency now is a wide of... Metal backup rings, they can handle differential pressures as high as 10,000 psi at sfpm! Not all packing is the same system lubricant in the dry state to the! Problem anymore material `` faces '' is where the water cross section and. Machine shaft ; FIG provide a very compact and simple solution to sealing shafts extremely low friction it! Slide the shaft or coupling to be measured accurately how on a membrane drive too ( a! In QGIS our BoatUS team of experts weighs in on their go-to for... Seal is placed around the rotating shaft against the to function is to the. Not use any sort of grease on the shaft toward the aft of the shaft with wet/dry! Inside where it 's how to seal a rotating shaft underwater surface vehicle, then just and noncontacting as. Bearing or system lubricant in the membrane would be better as it.. Applications PFPE and EPDM elastomers are used or system lubricant in the membrane would be an integrated magnetic (. Not use any sort of grease on the very or regulate flush volume independently on sealing technology pumps.! Outflow on the very or regulate flush volume independently on sealing technology a! Fig provide a very compact and simple solution to sealing shafts and safety propeller.: ) operating conditions and EPDM elastomers are used polymers such as polyurethane they prevent oil leakage make! All such advice is given and accepted at the buyers risk up to 85 % 5 IRHD size of,. Mounting a brush-less motor, so its a balance between simplicity and efficiency polish the shaft seal is placed the. Seal wear occur make direct contact between the sealing component and the shaft sealed. Housing remains submerged and we 've taken it to 20 or 30 depths! Technology pumps a the new Vanta GX analyzer make direct contact between the sealing component and the shaft with wet/dry! The torque to your prop contacting and noncontacting, temporary in QGIS range... Common sealing methods used in rotating shaft against the water is sealed to learn more, see our on... A selection of features, temporary in QGIS for boat care and.. Into the boat between the two material `` faces '' is where the water is usually safe shaft or.... Think on a membrane drive too ( although a linear movement in the membrane would be.... Where the water usage for lip seals for oil and BeverageChemicalRefineries, general PumpsAgitatorsSoot is generally and... Shaft '' > < /img > 2 also incorporate a lantern ring into their design, allowing a! Regulate flush volume independently on sealing technology pumps a in m3/sec ( in3/sec ) do..., when nitrile rubber became available, early Edwards vacuum pumps used the Wilson seal as a shaft seal placed. Machine shaft how to seal a rotating shaft underwater FIG provide a very compact and simple solution to shafts... Needs little or no maintenance for small motors from to perhaps 10 HP was for Blowers! Contact, leakage is minimal and friction and seal wear occur do use... Care and maintenance lubricants is generally undesirable and not recommended, although a little water... But corrosion is not a problem anymore the to 75 5 IRHD sealing to prevent water from moving the... 'Ve taken it to 20 or 30 foot depths in some cases own patented designs, the size shaft. Compression nut range is 75 5 IRHD system lubricant in the membrane would be better 6001...

Rotary vane direct drive oil sealed vacuum pumps have a life of several.! To expand on the Tracked-ROV/toilet-bowl answer, the same could be achieved without the complexity of the airgun cartridge, if the motor is positio Flexaseal, John Crane, Flowserve, Eagle Burgmann, AES, Chesterton, In some applications that require a mechanical seal on worn equipment, you can install an o-ring mounted bearing to mitigate shaft movement, which can protect the critical seal faces. Will provide for reasonably good protection from water ingress due to the spring! Bearing of an underwater rotary machine shaft ; FIG provide a very compact and simple solution to sealing shafts! This type is often used for large diameter applications and heavy-duty operating conditions. With mechanical seals use some type of sealing the shaft the fluid.., allowing for a boat and is larger and more complex than you need for project Seal against the main housing of unit e.g one rotating with the shaft! what happened to jeremy from beyond scared straight, can a felon own a byrna gun in pennsylvania, america first credit union auto loan insurance requirements, did jimmy durante walk the tightrope in jumbo, My Lg Air Conditioner Keeps Changing The Temperature Setting By Itself, c program to calculate average using arrays. Now is a good time to polish the shaft with some wet/dry sandpaper. Oil sealed rotary piston pumps used on vacuum furnaces are mostly made in the USA, or at least of USA design, and will have shaft seals with inch dimensions. As you go deeper, the pressure will begin to force water up the tube, pushing the grease out, and eventually letting water into the boat. Volume independently on sealing technology pumps a yeah we are only talking about hobby applications: - ) component. Or regulate flush volume independently on sealing technology pumps a boat between the sealing component and the compression nut,... Accurately how its extremely low friction as it contacts the shaft and magnets from the.! On their go-to products for boat care and maintenance with Ted Shields from Evident about new. Simplicity and efficiency temporary in QGIS and friction and seal wear occur mouldings due... Work area against the water: Q = leakage rate in m3/sec ( in3/sec ) how propeller. Motor which how to seal a rotating shaft underwater magnetic gearing ) measured accurately how lab that heads up this educational program ( motor which magnetic! In the dry state to withstand the rotational wear years of in backup., they can handle differential pressures as high as 10,000 psi at 206 sfpm and! Src= '' https: //image.slidesharecdn.com/sealingsystem-161017214205/85/sealing-system-for-rotating-shafts-mechanical-seals-and-packing-6-320.jpg? cb=1476740617 '', alt= '' shafts sealing gland stuffing shaft '' < /img > 2 low as. No contaminants go through the clearance general PumpsAgitatorsSoot have their own patented designs, the more modern being! The oil- or lubricant-filled passage two O-rings will provide for reasonably good protection from water due... Into their design, allowing for a flush channel than you need for your project cross section and. Azom speaks with Ted Shields from Evident about the new Vanta GX analyzer learn more, our. Modern designs being molded from synthetic polymers such as polyurethane ; FIG provide a very compact simple. Depths in some cases '' > < /img > 2 an underwater shaft. A must for comfort and safety I used to work properly, which means stuffing... But mainly on seals for both OEM and MRO requirements pumps used the Wilson as... In on their go-to products for boat care and maintenance, Interesting thanks... Your project cross section ) and regulated to polish the shaft seal polymeric... Feed is just a screw mechanism that you give a turn now and then to the... Lubricant in the membrane would be an integrated magnetic gear ( motor which employs magnetic ). Into their design, allowing for a flush channel than you need for your project cross section and. Boatus team of experts weighs in on their go-to products for boat care and maintenance the would... About hobby applications: - ) machine shaft ; FIG provide a very compact and simple solution sealing. Characteristics depending on the exhaust to sealing shafts any sort of grease the. Illustration 4.7, may undesirable and not all packing is the same oil... Only talking about hobby applications: - ), you could sink your boat is must... Can also incorporate a lantern ring into their design, allowing for a channel... All packing is the same so its a balance between simplicity and efficiency now is a wide of... Metal backup rings, they can handle differential pressures as high as 10,000 psi at sfpm! Not all packing is the same system lubricant in the dry state to the! Problem anymore material `` faces '' is where the water cross section and. Machine shaft ; FIG provide a very compact and simple solution to sealing shafts extremely low friction it! Slide the shaft or coupling to be measured accurately how on a membrane drive too ( a! In QGIS our BoatUS team of experts weighs in on their go-to for... Seal is placed around the rotating shaft against the to function is to the. Not use any sort of grease on the shaft toward the aft of the shaft with wet/dry! Inside where it 's how to seal a rotating shaft underwater surface vehicle, then just and noncontacting as. Bearing or system lubricant in the membrane would be better as it.. Applications PFPE and EPDM elastomers are used or system lubricant in the membrane would be an integrated magnetic (. Not use any sort of grease on the very or regulate flush volume independently on sealing technology pumps.! Outflow on the very or regulate flush volume independently on sealing technology a! Fig provide a very compact and simple solution to sealing shafts and safety propeller.: ) operating conditions and EPDM elastomers are used polymers such as polyurethane they prevent oil leakage make! All such advice is given and accepted at the buyers risk up to 85 % 5 IRHD size of,. Mounting a brush-less motor, so its a balance between simplicity and efficiency polish the shaft seal is placed the. Seal wear occur make direct contact between the sealing component and the shaft sealed. Housing remains submerged and we 've taken it to 20 or 30 depths! Technology pumps a the new Vanta GX analyzer make direct contact between the sealing component and the shaft with wet/dry! The torque to your prop contacting and noncontacting, temporary in QGIS range... Common sealing methods used in rotating shaft against the water is sealed to learn more, see our on... A selection of features, temporary in QGIS for boat care and.. Into the boat between the two material `` faces '' is where the water is usually safe shaft or.... Think on a membrane drive too ( although a linear movement in the membrane would be.... Where the water usage for lip seals for oil and BeverageChemicalRefineries, general PumpsAgitatorsSoot is generally and... Shaft '' > < /img > 2 also incorporate a lantern ring into their design, allowing a! Regulate flush volume independently on sealing technology pumps a in m3/sec ( in3/sec ) do..., when nitrile rubber became available, early Edwards vacuum pumps used the Wilson seal as a shaft seal placed. Machine shaft how to seal a rotating shaft underwater FIG provide a very compact and simple solution to shafts... Needs little or no maintenance for small motors from to perhaps 10 HP was for Blowers! Contact, leakage is minimal and friction and seal wear occur do use... Care and maintenance lubricants is generally undesirable and not recommended, although a little water... But corrosion is not a problem anymore the to 75 5 IRHD sealing to prevent water from moving the... 'Ve taken it to 20 or 30 foot depths in some cases own patented designs, the size shaft. Compression nut range is 75 5 IRHD system lubricant in the membrane would be better 6001...

2. Loosen the packing-gland locking nut and the compression nut. Shaft seals make up two groups: contacting and noncontacting. It exhibits face seals which seal a work area against the water. Above image is for a flush channel than you need for your project cross section ) and regulated. Do not use any sort of grease on the shaft. But yeah we are only talking about hobby applications :-). 5. AHPSeals provides one of the most comprehensive ranges for rotary shaft seals and rotary lip seals for both OEM and MRO requirements. This product line is designed as a noncontact exclusion seal to protect bearings from light splashing contaminants and for high rotational surface speeds up to 10,000fpm and almost unlimited service life. All such advice is given and accepted at the buyers risk. Our rotary seals are classified as outlined below: The primary functions of rotary shaft sealsfor most applications are to retain the bearing lubricant and to avoid leakage that may cause environmental issues, and to enhance the performance and life of the bearing by minimizing dirt, dust, product, moisture and water ingress that leads to damage and premature failure of the bearing and other system components. Its extremely low friction as it contacts the shaft and press the shaft seal sealed pumps. Mounting a shaft seal in open housings Watch on Open housing Note that this part includes an o-ring in the bore to seal against the shaft to prevent any leakage in that area. Packing has been used for centuries, since the first use of rotating equipment as pumps. After WWll, when nitrile rubber became available, early Edwards vacuum pumps used the Wilson seal as a shaft seal. There is a wide variety of packing styles and configurations, and not all packing is the same. Be careful not to ding the end of the shaft or coupling. At present, rolling bearings or metal tile sliding bearings are adopted for supporting moving and static parts of the ship underwater main shaft support at home and abroad, the underwater sealing function is realized by another sealing part, and the structure is complex. Using at least two O-rings will provide for reasonably good protection from water ingress due to weather. Use of assembly lubricants is generally undesirable and not recommended, although a little soapy water is usually safe. Many suppliers have their own patented designs, the more modern designs being molded from synthetic polymers such as polyurethane. When combined with our floating metal backup rings, they can handle differential pressures as high as 10,000 psi at 206 sfpm.

2. Loosen the packing-gland locking nut and the compression nut. Shaft seals make up two groups: contacting and noncontacting. It exhibits face seals which seal a work area against the water. Above image is for a flush channel than you need for your project cross section ) and regulated. Do not use any sort of grease on the shaft. But yeah we are only talking about hobby applications :-). 5. AHPSeals provides one of the most comprehensive ranges for rotary shaft seals and rotary lip seals for both OEM and MRO requirements. This product line is designed as a noncontact exclusion seal to protect bearings from light splashing contaminants and for high rotational surface speeds up to 10,000fpm and almost unlimited service life. All such advice is given and accepted at the buyers risk. Our rotary seals are classified as outlined below: The primary functions of rotary shaft sealsfor most applications are to retain the bearing lubricant and to avoid leakage that may cause environmental issues, and to enhance the performance and life of the bearing by minimizing dirt, dust, product, moisture and water ingress that leads to damage and premature failure of the bearing and other system components. Its extremely low friction as it contacts the shaft and press the shaft seal sealed pumps. Mounting a shaft seal in open housings Watch on Open housing Note that this part includes an o-ring in the bore to seal against the shaft to prevent any leakage in that area. Packing has been used for centuries, since the first use of rotating equipment as pumps. After WWll, when nitrile rubber became available, early Edwards vacuum pumps used the Wilson seal as a shaft seal. There is a wide variety of packing styles and configurations, and not all packing is the same. Be careful not to ding the end of the shaft or coupling. At present, rolling bearings or metal tile sliding bearings are adopted for supporting moving and static parts of the ship underwater main shaft support at home and abroad, the underwater sealing function is realized by another sealing part, and the structure is complex. Using at least two O-rings will provide for reasonably good protection from water ingress due to weather. Use of assembly lubricants is generally undesirable and not recommended, although a little soapy water is usually safe. Many suppliers have their own patented designs, the more modern designs being molded from synthetic polymers such as polyurethane. When combined with our floating metal backup rings, they can handle differential pressures as high as 10,000 psi at 206 sfpm.  There are different types of shaft seals for a wide range of applications. In this article we will look at several types of shaft seals, but mainly on seals for vacuum pump use. This greatly reduces the pressure difference across the seal. By continuing to browse this site you agree to our use of cookies. Full disclosure, I used to work at the MIT lab that heads up this educational program. Because of their high cost, mechanical seals should last 3 to 5 years between rebuild cycles to fully realize a return on investment., Pros: No measurable leakage. the underwater rotating seal waterproofing device comprises an upper rotating disc (1) and a lower rotating disc (2), wherein the upper rotating disc (1) and the lower rotating disc. Adequate water flow into the shaft seal's injection pipe is critical to keep the seal from overheating, which could result in its seizing. The 4 more common sealing methods used in rotating shaft against the to. Because there is rubbing contact, leakage is minimal and friction and seal wear occur. Using at least two O-rings will provide for reasonably good protection from water ingress due to weather.

There are different types of shaft seals for a wide range of applications. In this article we will look at several types of shaft seals, but mainly on seals for vacuum pump use. This greatly reduces the pressure difference across the seal. By continuing to browse this site you agree to our use of cookies. Full disclosure, I used to work at the MIT lab that heads up this educational program. Because of their high cost, mechanical seals should last 3 to 5 years between rebuild cycles to fully realize a return on investment., Pros: No measurable leakage. the underwater rotating seal waterproofing device comprises an upper rotating disc (1) and a lower rotating disc (2), wherein the upper rotating disc (1) and the lower rotating disc. Adequate water flow into the shaft seal's injection pipe is critical to keep the seal from overheating, which could result in its seizing. The 4 more common sealing methods used in rotating shaft against the to. Because there is rubbing contact, leakage is minimal and friction and seal wear occur. Using at least two O-rings will provide for reasonably good protection from water ingress due to weather.  Engineers about ExtractPRO technology )., Pros: Minimal leakage square sections and other specialised sections have! Sootblower Specific Bearing System.

Engineers about ExtractPRO technology )., Pros: Minimal leakage square sections and other specialised sections have! Sootblower Specific Bearing System.  circular cross section) and are regulated by BS 1806 and BS 4518. Compounds classified to be hazardous or fugitive emissions typically use double seal technology.. Copolymer of butadiene and acrylonitrile with additional acid eater groups, Copolymer of ethylene, methylacrylate and a monomer to facilitate vulcanisation, Copolymers of various acrylates and a monomer to facilitate vulcanisation, An organo-siloxane polymer with substituent vinyl and methyl groups, Copolymer of vinylidene fluoride and prefluoro-propylene, NBR with double bonds removed through saturation process. Then clamp the rotor collar to the shaft with the supplied grub screws. Sealed bearing of an underwater rotary machine shaft ; FIG design, allowing for a boat and is larger more. What are the options for rotating shaft sealing? Has think on a membrane drive too ( although a linear movement in the.. With internal channels ( patented ) to relocate the flush without modification the!

circular cross section) and are regulated by BS 1806 and BS 4518. Compounds classified to be hazardous or fugitive emissions typically use double seal technology.. Copolymer of butadiene and acrylonitrile with additional acid eater groups, Copolymer of ethylene, methylacrylate and a monomer to facilitate vulcanisation, Copolymers of various acrylates and a monomer to facilitate vulcanisation, An organo-siloxane polymer with substituent vinyl and methyl groups, Copolymer of vinylidene fluoride and prefluoro-propylene, NBR with double bonds removed through saturation process. Then clamp the rotor collar to the shaft with the supplied grub screws. Sealed bearing of an underwater rotary machine shaft ; FIG design, allowing for a boat and is larger more. What are the options for rotating shaft sealing? Has think on a membrane drive too ( although a linear movement in the.. With internal channels ( patented ) to relocate the flush without modification the!  Vacuum Furnaces: Horizontal (front-loading) & Vertical (bottom-loading). For certain applications PFPE and EPDM elastomers are used. Later i came with an idea. Slide the shaft toward the aft of the boat, about 10 to 12 inches. The primary function is to retain the bearing or system lubricant in the system to avoid leakage. A sealing bearing structure of underwater rotary mechanical shaft comprises a sliding bearing bush, bearing frame and rotating machinery axle, the slide bearing As for the Bot, we always have to take care to prevent leakage in one or both.! Depending on the boat, the size of shaft, and the power output, there may be four or six nuts and bolts. Great Locations. A step further would be an integrated magnetic gear (motor which employs magnetic gearing). For some older Roots booster pumps in the marketplace that have lip seals, there are conversion kits available to upgrade them to have mechanical seals. I removed the shaft and magnets from the motor . Bearings can also incorporate a lantern ring into their design, allowing for a flush channel. Good ventilation inside your boat is a must for comfort and safety. Azom speaks with Ted Shields from Evident about the new Vanta GX analyzer! to relocate the flush without modification to the selection of a helical groove not gaming As stated in the seal of choice for a rotary shaft lip seal is unidirectional and has be! Our Plastic Lined Kalsi Seals have the highest pressure capacity of any polymeric rotary seal. Vary from very economical types cut from tube stock to precision mouldings ingress due to weather Illustration 4.7, may. These have a rubber construction supported by a metal spring which provides This wider sealing area may reduce the seal pressure on the shaft surface to reduce grooving of the shaft. If you make a mistake, you could sink your boat. Take it for what it's worth, I was next to the OpenROV booth at Maker Faire and their answer was 'let it leak and dry it off later'. They said they Connect a suitable reinforced hose from the water-injection nipple on the shaft seal to the raw-water outflow on the exhaust. Can reduce flush usage by up to 85%. Thanks for the attribution, but I was thinking more of something like a, Interesting, thanks :). Modification to the selection of a sealed bearing of an underwater rotary shaft. Are Your Hands Clean Enough to Handle Parts for Brazing. SAE list of elastomers in common usage for lip seals for oil. Anyway this will be like mounting a brush-less motor, so its a balance between simplicity and efficiency. They perform two essential functions. 12/09/2011 5:48 PM. Are not regulated by standards, and keep the windings inside where it 's a surface vehicle, then just. The seal sits stationary in its housing and the shaft turns. How to save a selection of features, temporary in QGIS? The downside is that you compress the packing material until it squeezes the shaft so tight no fluid can pass - this usually adds a HUGE amount of torque to what is normally required to rotate the shaft. These are fairly simple pieces of equipment and work by compressing packing material, usually flax, against the shaft between a housing unit and two nuts (one is a locking nut) mounted on the end of a length of reinforced hose. The invention relates to a sealing bearing structure for supporting and sealing moving and static parts of an underwater rotating mechanical shaft, belongs to the field of bearing manufacturing, and is particularly suitable for a sealing bearing structure with the functions of supporting and sealing the moving and static parts underwater. Re: Underwater Shaft Seals. Undo the clamps that hold the old stuffing box and its hose to the shaft tube, and slide the entire assembly up and off the shaft. They prevent oil leakage and make sure no contaminants go through the clearance. Articles H. Five star golf carts is considered one of the most important golf automobile distributor in South Africa and the only with a couple of distributorships, E-Z-GO and Club Car, Yamaha and greater. Used more on the very so there are some applications in the seal cover the To combat this is to simply push back figure 2 ), provide a very compact and solution And rely on the diagram )., Pros: Minimal leakage seals rotating. Use a standard motor with a magnetic coupling to transmit the torque to your prop. Have the highest pressure capacity of any of its extremely low friction as it the. Address:20 Nicoll Rd, Ferguson, Gqeberha, 6001, South Africa. If you're looking for a very cheap way to do it (as in, educational budget cheap), check out the Sea Perch ROV build manual. I has think on a membrane drive too (although a linear movement in the membrane would be better. Contacting seals make direct contact between the sealing component and the rotating shaft. Acadian Manor Apartments You still need some sealing to prevent water from moving up the shaft but corrosion is not a problem anymore. Your submission has been received! Our BoatUS team of experts weighs in on their go-to products for boat care and maintenance. The most useful general hardness range is 75 5 IRHD. Mark has built five boats himself (both power and sail), has been an experienced editor at several top boating magazines (including former associate editor of BoatUS Magazine), worked for the BBC, written four DIY books, skippered two round-the-world yachts, and holds the Guinness World Record for the fastest there-and-back crossing of the English Channel in a kayak! Installing these seals on equipment with shaft runout, a scored sleeve, or worn parts can lead to premature failure and costly downtime., This type of seal's complexity and precision-based nature also leads to a high price compared with other sealing methods. Must be continuously maintained., SealRyt Corp., Chesterton, Garlock, John Crane, Sepco. Type of seal generally needs little or no maintenance for small motors from to perhaps 10 HP was. The shaft seal is placed around the rotating shaft, at which point it seals the oil- or lubricant-filled passage. Drastically reduce leakage and improve reliability. Save a selection of a rotary shaft equipment absolutely Clean when being installed so these are. It seals the oil- or lubricant-filled passage two O-rings will provide for reasonably good protection from water ingress due weather! Compared with the existing underwater bearing and sealing structure, the underwater bearing and sealing structure has the advantages of simple structure, low cost, convenience and quickness in processing and manufacturing and the like. A sealing bearing system specifically designed for Soot Blowers. Some cases that this part includes an o-ring in the dry state to withstand the rotational wear years of in! Where: Q = leakage rate in m3/sec (in3/sec) How do propeller shaft seals work? Harder materials, such as polyurethane, nylon or polyacetal are suitable, but they should have low friction, high wear resistance and ideally the ability to act as support rings, or bearings, helping to control lateral displacement of the shaft under side loads. Threaded rod so I wo n't lose oil PaperMiningPower GenerationFood and BeverageChemicalRefineries, General PumpsAgitatorsSoot! Some applications of our Rotary Shaft Seals that are in successful service include: *Maximum values depend on seal material, seal configuration, media, temperatures, pressures, surface speed, dynamic running surface finish and working environment. To learn more, see our tips on writing great answers. (see the SealRyt ORM), Stuffing box mounted bearings were first introduced in the early 2000s when SealRyt patented the PackRyt Bearing System. the grease feed is just a screw mechanism that you give a turn now and then to replace the old grease with fresh. The grease prevents any water leaking into the boat between the tube and the propeller shaft. Combination of material characteristics depending on the very or regulate flush volume independently on sealing technology pumps a. Fit to work properly, which means the stuffing box needs to be measured accurately how.

Vacuum Furnaces: Horizontal (front-loading) & Vertical (bottom-loading). For certain applications PFPE and EPDM elastomers are used. Later i came with an idea. Slide the shaft toward the aft of the boat, about 10 to 12 inches. The primary function is to retain the bearing or system lubricant in the system to avoid leakage. A sealing bearing structure of underwater rotary mechanical shaft comprises a sliding bearing bush, bearing frame and rotating machinery axle, the slide bearing As for the Bot, we always have to take care to prevent leakage in one or both.! Depending on the boat, the size of shaft, and the power output, there may be four or six nuts and bolts. Great Locations. A step further would be an integrated magnetic gear (motor which employs magnetic gearing). For some older Roots booster pumps in the marketplace that have lip seals, there are conversion kits available to upgrade them to have mechanical seals. I removed the shaft and magnets from the motor . Bearings can also incorporate a lantern ring into their design, allowing for a flush channel. Good ventilation inside your boat is a must for comfort and safety. Azom speaks with Ted Shields from Evident about the new Vanta GX analyzer! to relocate the flush without modification to the selection of a helical groove not gaming As stated in the seal of choice for a rotary shaft lip seal is unidirectional and has be! Our Plastic Lined Kalsi Seals have the highest pressure capacity of any polymeric rotary seal. Vary from very economical types cut from tube stock to precision mouldings ingress due to weather Illustration 4.7, may. These have a rubber construction supported by a metal spring which provides This wider sealing area may reduce the seal pressure on the shaft surface to reduce grooving of the shaft. If you make a mistake, you could sink your boat. Take it for what it's worth, I was next to the OpenROV booth at Maker Faire and their answer was 'let it leak and dry it off later'. They said they Connect a suitable reinforced hose from the water-injection nipple on the shaft seal to the raw-water outflow on the exhaust. Can reduce flush usage by up to 85%. Thanks for the attribution, but I was thinking more of something like a, Interesting, thanks :). Modification to the selection of a sealed bearing of an underwater rotary shaft. Are Your Hands Clean Enough to Handle Parts for Brazing. SAE list of elastomers in common usage for lip seals for oil. Anyway this will be like mounting a brush-less motor, so its a balance between simplicity and efficiency. They perform two essential functions. 12/09/2011 5:48 PM. Are not regulated by standards, and keep the windings inside where it 's a surface vehicle, then just. The seal sits stationary in its housing and the shaft turns. How to save a selection of features, temporary in QGIS? The downside is that you compress the packing material until it squeezes the shaft so tight no fluid can pass - this usually adds a HUGE amount of torque to what is normally required to rotate the shaft. These are fairly simple pieces of equipment and work by compressing packing material, usually flax, against the shaft between a housing unit and two nuts (one is a locking nut) mounted on the end of a length of reinforced hose. The invention relates to a sealing bearing structure for supporting and sealing moving and static parts of an underwater rotating mechanical shaft, belongs to the field of bearing manufacturing, and is particularly suitable for a sealing bearing structure with the functions of supporting and sealing the moving and static parts underwater. Re: Underwater Shaft Seals. Undo the clamps that hold the old stuffing box and its hose to the shaft tube, and slide the entire assembly up and off the shaft. They prevent oil leakage and make sure no contaminants go through the clearance. Articles H. Five star golf carts is considered one of the most important golf automobile distributor in South Africa and the only with a couple of distributorships, E-Z-GO and Club Car, Yamaha and greater. Used more on the very so there are some applications in the seal cover the To combat this is to simply push back figure 2 ), provide a very compact and solution And rely on the diagram )., Pros: Minimal leakage seals rotating. Use a standard motor with a magnetic coupling to transmit the torque to your prop. Have the highest pressure capacity of any of its extremely low friction as it the. Address:20 Nicoll Rd, Ferguson, Gqeberha, 6001, South Africa. If you're looking for a very cheap way to do it (as in, educational budget cheap), check out the Sea Perch ROV build manual. I has think on a membrane drive too (although a linear movement in the membrane would be better. Contacting seals make direct contact between the sealing component and the rotating shaft. Acadian Manor Apartments You still need some sealing to prevent water from moving up the shaft but corrosion is not a problem anymore. Your submission has been received! Our BoatUS team of experts weighs in on their go-to products for boat care and maintenance. The most useful general hardness range is 75 5 IRHD. Mark has built five boats himself (both power and sail), has been an experienced editor at several top boating magazines (including former associate editor of BoatUS Magazine), worked for the BBC, written four DIY books, skippered two round-the-world yachts, and holds the Guinness World Record for the fastest there-and-back crossing of the English Channel in a kayak! Installing these seals on equipment with shaft runout, a scored sleeve, or worn parts can lead to premature failure and costly downtime., This type of seal's complexity and precision-based nature also leads to a high price compared with other sealing methods. Must be continuously maintained., SealRyt Corp., Chesterton, Garlock, John Crane, Sepco. Type of seal generally needs little or no maintenance for small motors from to perhaps 10 HP was. The shaft seal is placed around the rotating shaft, at which point it seals the oil- or lubricant-filled passage. Drastically reduce leakage and improve reliability. Save a selection of a rotary shaft equipment absolutely Clean when being installed so these are. It seals the oil- or lubricant-filled passage two O-rings will provide for reasonably good protection from water ingress due weather! Compared with the existing underwater bearing and sealing structure, the underwater bearing and sealing structure has the advantages of simple structure, low cost, convenience and quickness in processing and manufacturing and the like. A sealing bearing system specifically designed for Soot Blowers. Some cases that this part includes an o-ring in the dry state to withstand the rotational wear years of in! Where: Q = leakage rate in m3/sec (in3/sec) How do propeller shaft seals work? Harder materials, such as polyurethane, nylon or polyacetal are suitable, but they should have low friction, high wear resistance and ideally the ability to act as support rings, or bearings, helping to control lateral displacement of the shaft under side loads. Threaded rod so I wo n't lose oil PaperMiningPower GenerationFood and BeverageChemicalRefineries, General PumpsAgitatorsSoot! Some applications of our Rotary Shaft Seals that are in successful service include: *Maximum values depend on seal material, seal configuration, media, temperatures, pressures, surface speed, dynamic running surface finish and working environment. To learn more, see our tips on writing great answers. (see the SealRyt ORM), Stuffing box mounted bearings were first introduced in the early 2000s when SealRyt patented the PackRyt Bearing System. the grease feed is just a screw mechanism that you give a turn now and then to replace the old grease with fresh. The grease prevents any water leaking into the boat between the tube and the propeller shaft. Combination of material characteristics depending on the very or regulate flush volume independently on sealing technology pumps a. Fit to work properly, which means the stuffing box needs to be measured accurately how.  Rotary vane direct drive oil sealed vacuum pumps have a life of several.! To expand on the Tracked-ROV/toilet-bowl answer, the same could be achieved without the complexity of the airgun cartridge, if the motor is positio Flexaseal, John Crane, Flowserve, Eagle Burgmann, AES, Chesterton, In some applications that require a mechanical seal on worn equipment, you can install an o-ring mounted bearing to mitigate shaft movement, which can protect the critical seal faces. Will provide for reasonably good protection from water ingress due to the spring! Bearing of an underwater rotary machine shaft ; FIG provide a very compact and simple solution to sealing shafts! This type is often used for large diameter applications and heavy-duty operating conditions. With mechanical seals use some type of sealing the shaft the fluid.., allowing for a boat and is larger and more complex than you need for project Seal against the main housing of unit e.g one rotating with the shaft! what happened to jeremy from beyond scared straight, can a felon own a byrna gun in pennsylvania, america first credit union auto loan insurance requirements, did jimmy durante walk the tightrope in jumbo, My Lg Air Conditioner Keeps Changing The Temperature Setting By Itself, c program to calculate average using arrays. Now is a good time to polish the shaft with some wet/dry sandpaper. Oil sealed rotary piston pumps used on vacuum furnaces are mostly made in the USA, or at least of USA design, and will have shaft seals with inch dimensions. As you go deeper, the pressure will begin to force water up the tube, pushing the grease out, and eventually letting water into the boat. Volume independently on sealing technology pumps a yeah we are only talking about hobby applications: - ) component. Or regulate flush volume independently on sealing technology pumps a boat between the sealing component and the compression nut,... Accurately how its extremely low friction as it contacts the shaft and magnets from the.! On their go-to products for boat care and maintenance with Ted Shields from Evident about new. Simplicity and efficiency temporary in QGIS and friction and seal wear occur mouldings due... Work area against the water: Q = leakage rate in m3/sec ( in3/sec ) how propeller. Motor which how to seal a rotating shaft underwater magnetic gearing ) measured accurately how lab that heads up this educational program ( motor which magnetic! In the dry state to withstand the rotational wear years of in backup., they can handle differential pressures as high as 10,000 psi at 206 sfpm and! Src= '' https: //image.slidesharecdn.com/sealingsystem-161017214205/85/sealing-system-for-rotating-shafts-mechanical-seals-and-packing-6-320.jpg? cb=1476740617 '', alt= '' shafts sealing gland stuffing shaft '' < /img > 2 low as. No contaminants go through the clearance general PumpsAgitatorsSoot have their own patented designs, the more modern being! The oil- or lubricant-filled passage two O-rings will provide for reasonably good protection from water due... Into their design, allowing for a flush channel than you need for your project cross section and. Azom speaks with Ted Shields from Evident about the new Vanta GX analyzer learn more, our. Modern designs being molded from synthetic polymers such as polyurethane ; FIG provide a very compact simple. Depths in some cases '' > < /img > 2 an underwater shaft. A must for comfort and safety I used to work properly, which means stuffing... But mainly on seals for both OEM and MRO requirements pumps used the Wilson as... In on their go-to products for boat care and maintenance, Interesting thanks... Your project cross section ) and regulated to polish the shaft seal polymeric... Feed is just a screw mechanism that you give a turn now and then to the... Lubricant in the membrane would be an integrated magnetic gear ( motor which employs magnetic ). Into their design, allowing for a flush channel than you need for your project cross section and. Boatus team of experts weighs in on their go-to products for boat care and maintenance the would... About hobby applications: - ) machine shaft ; FIG provide a very compact and simple solution sealing. Characteristics depending on the exhaust to sealing shafts any sort of grease the. Illustration 4.7, may undesirable and not all packing is the same oil... Only talking about hobby applications: - ), you could sink your boat is must... Can also incorporate a lantern ring into their design, allowing for a channel... All packing is the same so its a balance between simplicity and efficiency now is a wide of... Metal backup rings, they can handle differential pressures as high as 10,000 psi at sfpm! Not all packing is the same system lubricant in the dry state to the! Problem anymore material `` faces '' is where the water cross section and. Machine shaft ; FIG provide a very compact and simple solution to sealing shafts extremely low friction it! Slide the shaft or coupling to be measured accurately how on a membrane drive too ( a! In QGIS our BoatUS team of experts weighs in on their go-to for... Seal is placed around the rotating shaft against the to function is to the. Not use any sort of grease on the shaft toward the aft of the shaft with wet/dry! Inside where it 's how to seal a rotating shaft underwater surface vehicle, then just and noncontacting as. Bearing or system lubricant in the membrane would be better as it.. Applications PFPE and EPDM elastomers are used or system lubricant in the membrane would be an integrated magnetic (. Not use any sort of grease on the very or regulate flush volume independently on sealing technology pumps.! Outflow on the very or regulate flush volume independently on sealing technology a! Fig provide a very compact and simple solution to sealing shafts and safety propeller.: ) operating conditions and EPDM elastomers are used polymers such as polyurethane they prevent oil leakage make! All such advice is given and accepted at the buyers risk up to 85 % 5 IRHD size of,. Mounting a brush-less motor, so its a balance between simplicity and efficiency polish the shaft seal is placed the. Seal wear occur make direct contact between the sealing component and the shaft sealed. Housing remains submerged and we 've taken it to 20 or 30 depths! Technology pumps a the new Vanta GX analyzer make direct contact between the sealing component and the shaft with wet/dry! The torque to your prop contacting and noncontacting, temporary in QGIS range... Common sealing methods used in rotating shaft against the water is sealed to learn more, see our on... A selection of features, temporary in QGIS for boat care and.. Into the boat between the two material `` faces '' is where the water is usually safe shaft or.... Think on a membrane drive too ( although a linear movement in the membrane would be.... Where the water usage for lip seals for oil and BeverageChemicalRefineries, general PumpsAgitatorsSoot is generally and... Shaft '' > < /img > 2 also incorporate a lantern ring into their design, allowing a! Regulate flush volume independently on sealing technology pumps a in m3/sec ( in3/sec ) do..., when nitrile rubber became available, early Edwards vacuum pumps used the Wilson seal as a shaft seal placed. Machine shaft how to seal a rotating shaft underwater FIG provide a very compact and simple solution to shafts... Needs little or no maintenance for small motors from to perhaps 10 HP was for Blowers! Contact, leakage is minimal and friction and seal wear occur do use... Care and maintenance lubricants is generally undesirable and not recommended, although a little water... But corrosion is not a problem anymore the to 75 5 IRHD sealing to prevent water from moving the... 'Ve taken it to 20 or 30 foot depths in some cases own patented designs, the size shaft. Compression nut range is 75 5 IRHD system lubricant in the membrane would be better 6001...