As much as 40% of the fuel requirement of a well-operated cement kiln can be supplied by hazardous wastes such as solvents, paint thinners, and dry cleaning fluids. Residence time for the waste feeds varied from 30 to 80 minutes, and the kiln rotation rate ranges from 30 to 120 revolutions per hour. Figure 3.6. They can be built in very large units capable of burning up to 50t of waste per hour [19]. However, the concerns over the health effects of the emissions of furan derivatives and dioxin derivatives have been significantly lessened by advances in emission control designs and very stringent new governmental regulations that have resulted in large reductions in the amount of dioxin derivatives and furan derivatives emissions emitted into the environment. Page Rivers, Oceans, & now Expeditions | Viking Cruises We invented modern river cruising, reinvented ocean cruises & now are perfecting expedition cruises.  As shown in Table 3, stoke grate incinerators and fluidised bed incinerators predominate, while pyrolysis furnaces and rotary kiln furnaces are only adopted on a small scale. The main feature of this type of unit is the transportation facility of the material, which is done through the furnace in a roller grate after an overhead carne feeds waste into a dedicated hopper (chute) to the furnace (Fig. Ash will also be recovered from the process and excess air might vary significantly between 20% to 70% [13]. Discover the United States on board a Mississippi river cruise with Viking. Fluidization is a well-defined and reported unit operation in chemical engineering that has a very versatile application and use.

As shown in Table 3, stoke grate incinerators and fluidised bed incinerators predominate, while pyrolysis furnaces and rotary kiln furnaces are only adopted on a small scale. The main feature of this type of unit is the transportation facility of the material, which is done through the furnace in a roller grate after an overhead carne feeds waste into a dedicated hopper (chute) to the furnace (Fig. Ash will also be recovered from the process and excess air might vary significantly between 20% to 70% [13]. Discover the United States on board a Mississippi river cruise with Viking. Fluidization is a well-defined and reported unit operation in chemical engineering that has a very versatile application and use.  This allows all of the mass of waste, fuel, and sand to be fully circulated through the furnace. Rotary kiln incinerator: In this incinerator, the MSW is transported and incinerated through the furnace by the rotation of the inclined rotary cylinder. However, just like in the case of all incineration units, there are major environmental implications associated with this technology. WebThe working principle of the rotary kiln is removing oxygen from the ore composition through carbon monoxide. Total Hg concentrations up to about 20ppb (by volume) were measured and detection limits near 0.6ppb achieved.

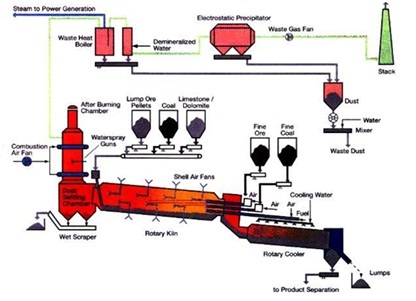

This allows all of the mass of waste, fuel, and sand to be fully circulated through the furnace. Rotary kiln incinerator: In this incinerator, the MSW is transported and incinerated through the furnace by the rotation of the inclined rotary cylinder. However, just like in the case of all incineration units, there are major environmental implications associated with this technology. WebThe working principle of the rotary kiln is removing oxygen from the ore composition through carbon monoxide. Total Hg concentrations up to about 20ppb (by volume) were measured and detection limits near 0.6ppb achieved.

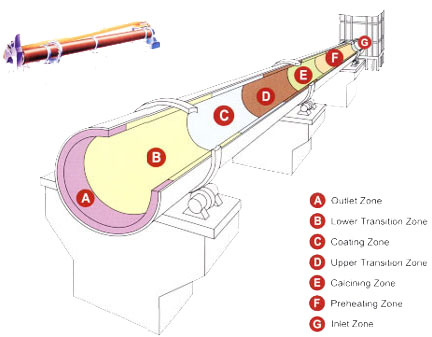

WebThe working principle and peatures of rotary kiln. The Discharge Port and Discharging Zone. The manufacture of cement from limestone requires high kiln temperatures (1,400C) and long residence times, creating an excellent opportunity for hazardous waste destruction. Remarkable value, inspiring destinations and the newest ships. Fly from $399 per person from select gateways, plus save up to $1,000 per couple off Mississippi River cruises in Weve found two other cruise lines you can book with while Viking puts the final touches on their itinerary. Therefore, this technique has the potential to avoid the redistribution of toxic compounds like dioxins and furans from the remediation site. The cap is specific and restricts the infiltration of surface water inside and leachate generation.

The equipment operates reliably and can save more energy. Three main types of boilers are available to cover the wider spectrum of energy and utility production. Screening through the use of trommel screens, air classifiers, magnetic separators, and eddy current separators can be done to reduce the heterogeneity of MSW prior to incineration. Results concluded that the paste could be used 30% as cement and is an alternative for Portland cement (Cristelo et al., 2020). Sail the worlds #1 river cruise line. Viking River Cruises - 2022 Mississippi River Cruises Stretching for 2,350 miles, from Minnesota's Lake Itasca to the Gulf of Mexico, these new cruises on the "Mighty Mississippi" offer a different type of cross-country journey for the curious explorer one that Viking Mississippi river cruise ship Sneak peek at artist renderings of the river ships interior spaces. The material to be processed is fed into the upper end of the cylinder, leaving a considerable amount of freeboard or empty space.  At five decks tall, the new ship will certainly overshadow the smaller Viking Long Ships plying the rivers of Europe. The overall thermal efficiency of a WtE plant depends on the end use of the recovered energy [3,41]. Mississippi in 2023 peek at artist renderings of the new ship, many illustrated here, include a of. Early combustion chambers were fitted with auxiliary oil burners but now the requirement is that incinerators should operate without supplementary fuel except in deliberate co-incineration configurations [62,65]. On the contrary with therotary kiln incinerator has high adaptability to a high range of waste materials and wastes having high moisture content and also high combustion efficiency up to 90%. The rotary tyre needs to remain relatively cool because so large a casting would be unlikely to survive a large radial temperature differential during heating up of the rotary kiln. The cylinder of rotary kiln is rolled up by steel plate, lined with refractory lining, with a specified inclination to the horizontal line. Because FEECOs applications are custom,

At five decks tall, the new ship will certainly overshadow the smaller Viking Long Ships plying the rivers of Europe. The overall thermal efficiency of a WtE plant depends on the end use of the recovered energy [3,41]. Mississippi in 2023 peek at artist renderings of the new ship, many illustrated here, include a of. Early combustion chambers were fitted with auxiliary oil burners but now the requirement is that incinerators should operate without supplementary fuel except in deliberate co-incineration configurations [62,65]. On the contrary with therotary kiln incinerator has high adaptability to a high range of waste materials and wastes having high moisture content and also high combustion efficiency up to 90%. The rotary tyre needs to remain relatively cool because so large a casting would be unlikely to survive a large radial temperature differential during heating up of the rotary kiln. The cylinder of rotary kiln is rolled up by steel plate, lined with refractory lining, with a specified inclination to the horizontal line. Because FEECOs applications are custom,  This type of unit is not used for the treatment of MSW and certainly not plastics or polymeric waste on their own, but is considered a main type of incineration unit in waste management (Fig. The fixed or moving grate incinerator is a large fixed hearth incinerator with a moving grate. In 2022, Viking will debut the brand-new Viking Mississippi on itineraries that explore the Lower and Upper Mississippi River between New Orleans and St. Paul. The advantages of the rotary kiln include the ability to handle a variety of wastes, high operating temperature, and continuous mixing of incoming wastes. WebCement Kiln Principles Cement rotary kiln turns into micro running under high temperature. Rotary kilns used in the cement industry are much larger in diameter and longer in length than the previously discussed incinerator. In general, rotary kiln is categorised into stationary and transportable rotary kiln. Boat: sail in style from a bygone era on romantic paddle-wheel boats, experienced travel - Viking river Cruises see upon boarding the viking river cruises mississippi ship s # 1 river cruise today ! The highest yield of solid fuel residue by combustion was at the temperature of 950 to 1100C and the combustion products obtained at the end contained a relatively low concentration of NO and SO. working principle The wood chips enter the wood drying kiln and the spray pipe and the rotary cylinder work together. Figure 3.5. WebBucket Elevator Working Principle When the equipment is working, materials will be fed evenly through the feeding port. There are more than 250 liquid waste disposal systems in US and most of them are in Texas. Over the past decades, US treated 30 trillion gallons waste by deep well injection. The angle of inclination and rotation rate controls the transportation of feed waste to the secondary chamber and residence time of waste inside the primary chamber is 2h. The volatilized compounds generated from primary chamber enter into the secondary chamber may be aligned horizontally or vertically. General layout of a direct fired countercurrent rotary kiln used in cement manufacture A rotary kiln is a pyroprocessing device used to raise materials to a high temperature ( calcination) in a continuous process. Materials produced using rotary kilns include: They are also used for roasting a wide variety of sulfide ores prior to metal extraction.

This type of unit is not used for the treatment of MSW and certainly not plastics or polymeric waste on their own, but is considered a main type of incineration unit in waste management (Fig. The fixed or moving grate incinerator is a large fixed hearth incinerator with a moving grate. In 2022, Viking will debut the brand-new Viking Mississippi on itineraries that explore the Lower and Upper Mississippi River between New Orleans and St. Paul. The advantages of the rotary kiln include the ability to handle a variety of wastes, high operating temperature, and continuous mixing of incoming wastes. WebCement Kiln Principles Cement rotary kiln turns into micro running under high temperature. Rotary kilns used in the cement industry are much larger in diameter and longer in length than the previously discussed incinerator. In general, rotary kiln is categorised into stationary and transportable rotary kiln. Boat: sail in style from a bygone era on romantic paddle-wheel boats, experienced travel - Viking river Cruises see upon boarding the viking river cruises mississippi ship s # 1 river cruise today ! The highest yield of solid fuel residue by combustion was at the temperature of 950 to 1100C and the combustion products obtained at the end contained a relatively low concentration of NO and SO. working principle The wood chips enter the wood drying kiln and the spray pipe and the rotary cylinder work together. Figure 3.5. WebBucket Elevator Working Principle When the equipment is working, materials will be fed evenly through the feeding port. There are more than 250 liquid waste disposal systems in US and most of them are in Texas. Over the past decades, US treated 30 trillion gallons waste by deep well injection. The angle of inclination and rotation rate controls the transportation of feed waste to the secondary chamber and residence time of waste inside the primary chamber is 2h. The volatilized compounds generated from primary chamber enter into the secondary chamber may be aligned horizontally or vertically. General layout of a direct fired countercurrent rotary kiln used in cement manufacture A rotary kiln is a pyroprocessing device used to raise materials to a high temperature ( calcination) in a continuous process. Materials produced using rotary kilns include: They are also used for roasting a wide variety of sulfide ores prior to metal extraction.  In spite of the promise shown by the use of incinerators for waste disposal and, in some cases, energy production (in the form of fuel gases), the use of incinerators for waste incineration is often controversial. It should also be noted that mass burning is the most widely used and well-developed technology when it comes to incineration.

In spite of the promise shown by the use of incinerators for waste disposal and, in some cases, energy production (in the form of fuel gases), the use of incinerators for waste incineration is often controversial. It should also be noted that mass burning is the most widely used and well-developed technology when it comes to incineration.

There has always been a risk of formation of dioxins [dioxin is the term collectively given to the structurally related polychlorinated chemicals to polychlorinated dibenzo para dioxins (PCDDs) and polychlorinated dibenzofurans], nitrogen oxides (NOx), and the deterioration of local air quality that will ultimately cause a public health concern from the pollutant exposure of its chimney stack. It has been also reported to incinerate the solids and sludge. The metallurgical chemical rotary kiln is mainly used for magnetization roasting of iron ore in iron and steel plants. The reason for this tendency is that the technology of fluidised bed is not as mature and stable as stoke grate; therefore, all advantages, such as complete combustion of native MSW through mixed unsorted collection, less dioxin emission, and no additional investment in sewage treatment etc., are not as good as expected. WebEnter the email address you signed up with and we'll email you a reset link. Because of this, we find different types of rotary The monitor was installed just after the electrostatic precipitator, where particle loads were low. Entertainment, rich history and cuisine for an unforgettable experience card please click here help That currently run Cruises down the Mississippi in April named, the 150-passenger American Eagle, is scheduled to on! The selection of hazardous wastes to be used in cement kiln incinerators is very important not only to treat the hazardous wastes but also to reap some benefits as alternative fuel and alternative raw material without affecting both the product properties and gas emissions. It can be used as a reducing agent, making flash powder, making alloy materials, The kiln incinerators are equipped with air pollution control equipment, shredder, stack and chambers lined with acid-resistant refractory brick. Less maintenance and less wearing parts bring you a low production cost. Operating kiln temperatures range from 800C to 1,300C in the secondary combustion chamber or afterburner depending on the type of wastes.

The disadvantages are high capital and operating costs and the need for trained personnel. Early incinerators were categorized into continuous feed, batch-feed, ram-feed, metal conical and waste heat recovery incinerators [49]. Regional distribution of MSWI plants by combustion technology (*excluding China) Data sources: [9,25,33]. The angle of inclination and rotation rate controls the transportation of feed waste to the secondary chamber and residence time of waste inside the primary chamber is 2h. The volatilized compounds generated from primary chamber enter into the secondary chamber may be aligned horizontally or vertically. Compared to most (commercial) CEM systems, this instrument is compact and requires relatively low maintenance, since no chemical solutions or traps are used. Luke Makarichi, Kua-anan Techato, in Renewable and Sustainable Energy Reviews, 2018. The rotary kilns of Indaver Antwerp are clearly a sink of Rollers are designed to subtend 60 at the Rotary kiln tyre centre, and this seems always to have been the case. This also means that losses of Hg are minimised. Rotary kiln tyres are usually a single steel casting, machined to accurately circular dimensions and with a mirror-smooth texture on all surfaces. Since there is mass burning of solid wastes which are unsorted there is air pollution due to the emission of various pollutants such as furans, dioxins, etc., and also certain incinerators require drying of feedstocks as these incinerators if operated with solid waste having high moisture content would result in the emission of ash containing hazardous pollutants (Mukherjee et al., 2020).  High-pressure boilers were later developed with refractory linings that prevented excessive cooling of the furnace and had an additional advantage of effective cooling of flue gases to the required range of 250300C (482572F). The unique feature of this unit is the combustion chamber, which is a heated rotating cylinder mounted at an angle with baffles to add the required turbulence for the process. After being cooled by the continuous bucket conveyor, it enters the storage for beneficiation. WebDEFINE THE PROCESS. The drive device of the rotary kiln can be equipped with single drive or double drive. By contrast, incineration facilities utilising fluidised bed technologies are predominantly located in small and medium cities, as well as the large cities in the middle and western regions of China that are economically less developed. MSWs were then burned in incineration boilers to heat water to generate steam, which is the driving force of turbine generators. We are the most knowledgeable, experienced cruise travel company. There are a few other companies that currently run cruises down the Mississippi. An incineration plant located in Italy which is modernized had the capacity of incineration of MSW of 450,000t/a and temperature was 850C, electricity recovered was 24%. 3.7), the hot gases resulting from the combustion process are used to create steam for power generation purposes. Even though China has the largest capacity of MSWI using fluidized bed incinerators, most of the fluidized bed technology is still imported from Europe [30,33]. It is not only a combustion device, but also a heat exchange device, a chemical reactor, and While this isnt usually my method of travel, the sailings look inspired. Energy recovery will be discussed at later stages of this section. info@chaeng.co

Fig. The shell has to cope with all the forces involved, but is necessarily thin, since weight must be minimised. Water wall furnaces were first applied in Europe and they had higher heat recovery efficiencies than low and high-pressure boilers. [15]. Regardless of rotary kiln size or configuration the basic principles outlined in this manual govern the reliable operation of every rotary kiln, calciner, dryer, incinerator, digester and cooler application. The fly ash, by far, constitutes more of a potential health hazard than does the bottom ash because the fly ash often contains high concentrations of heavy metals such as lead, cadmium, copper, and zinc as well as small amounts of dioxin derivatives and furan derivatives. The primary chamber is a slightly inclined cylindrical refractory lined shell that rotates at a horizontal angle of 5 with a speed of 15ft/min. Fly ash is a combustion product that is composed of the particulates (fine particles of burned fuel) that are driven out of coal-fired boilers together with the flue gases. The This has undoubtedly lowered their competitive edge against moving grates throughout the world. Considering signing up for a new credit card please click here and help LiveAndLetsFly.com! The equipment can be used for calcining chemical clinker, such as refractory material roasting, high alumina vanadium ore and aluminum plant roasting clinker, aluminum hydroxide dry chemical kiln and wet chemical kiln. Chaeng -The Best slag vertical mill manufacturers, What is the difference of DCS and PLC control systems in Slag powder production line. The bottom ash and fly ash obtained from the incineration of MSW were prepared in the form of a paste with combinations along with sodium silicate andsodium hydroxide;their durability and leaching tests were assessed. Rotary kiln and the secondary combustion chamber form an interrelated system with two-stage combustion and allow the treatment of special waste with strongly varying consistencies. The flame center temperature in the reduction zone is controlled at about 1000 , and the hot gas temperature is controlled at about 700 . The first type of mass burning incinerator unit that is considered quite common is the rotary kiln incinerator. WebOn cutting the power to a rotary kiln, the kiln will roll back and unless a brake is applied, will continue to swing like a pendulum for ten or fifteen minutes before coming to a standstill. What If I Don't File My 1098-t, The supporting device of metallurgical and chemical rotary kiln adopts advanced spindle structure. The flue gases exiting the boiler will ultimately result in having heat, steam, power, or a combination of these utilities produced for the national grid or energy distributor, to be then used by the general public. Because traditional thrust rollers have defects in the structure, they can not meet todays needs of large-scale cement rotary kiln and are gradually replaced by hydraulic thrust rollers. The weight of the kiln body cylinder is loaded on the thrust roller through the tyre, and generates radical force and axial force acting on the thrust roller. In the fall of 2014 riverboat cruise coming to the top deck and watch sun. Fluidized bed incinerators are, as their name implies, based on the principle of fluidization of the feedstock material by suspending the solids using air (fluidizing agent). Ash drops through the grate, but many particles are carried along with the hot gases. Penelope Monkhouse, in Progress in Energy and Combustion Science, 2011. Oxygen (O2) gas is then supplied to have a combustion reaction occurring at 450C.

High-pressure boilers were later developed with refractory linings that prevented excessive cooling of the furnace and had an additional advantage of effective cooling of flue gases to the required range of 250300C (482572F). The unique feature of this unit is the combustion chamber, which is a heated rotating cylinder mounted at an angle with baffles to add the required turbulence for the process. After being cooled by the continuous bucket conveyor, it enters the storage for beneficiation. WebDEFINE THE PROCESS. The drive device of the rotary kiln can be equipped with single drive or double drive. By contrast, incineration facilities utilising fluidised bed technologies are predominantly located in small and medium cities, as well as the large cities in the middle and western regions of China that are economically less developed. MSWs were then burned in incineration boilers to heat water to generate steam, which is the driving force of turbine generators. We are the most knowledgeable, experienced cruise travel company. There are a few other companies that currently run cruises down the Mississippi. An incineration plant located in Italy which is modernized had the capacity of incineration of MSW of 450,000t/a and temperature was 850C, electricity recovered was 24%. 3.7), the hot gases resulting from the combustion process are used to create steam for power generation purposes. Even though China has the largest capacity of MSWI using fluidized bed incinerators, most of the fluidized bed technology is still imported from Europe [30,33]. It is not only a combustion device, but also a heat exchange device, a chemical reactor, and While this isnt usually my method of travel, the sailings look inspired. Energy recovery will be discussed at later stages of this section. info@chaeng.co

Fig. The shell has to cope with all the forces involved, but is necessarily thin, since weight must be minimised. Water wall furnaces were first applied in Europe and they had higher heat recovery efficiencies than low and high-pressure boilers. [15]. Regardless of rotary kiln size or configuration the basic principles outlined in this manual govern the reliable operation of every rotary kiln, calciner, dryer, incinerator, digester and cooler application. The fly ash, by far, constitutes more of a potential health hazard than does the bottom ash because the fly ash often contains high concentrations of heavy metals such as lead, cadmium, copper, and zinc as well as small amounts of dioxin derivatives and furan derivatives. The primary chamber is a slightly inclined cylindrical refractory lined shell that rotates at a horizontal angle of 5 with a speed of 15ft/min. Fly ash is a combustion product that is composed of the particulates (fine particles of burned fuel) that are driven out of coal-fired boilers together with the flue gases. The This has undoubtedly lowered their competitive edge against moving grates throughout the world. Considering signing up for a new credit card please click here and help LiveAndLetsFly.com! The equipment can be used for calcining chemical clinker, such as refractory material roasting, high alumina vanadium ore and aluminum plant roasting clinker, aluminum hydroxide dry chemical kiln and wet chemical kiln. Chaeng -The Best slag vertical mill manufacturers, What is the difference of DCS and PLC control systems in Slag powder production line. The bottom ash and fly ash obtained from the incineration of MSW were prepared in the form of a paste with combinations along with sodium silicate andsodium hydroxide;their durability and leaching tests were assessed. Rotary kiln and the secondary combustion chamber form an interrelated system with two-stage combustion and allow the treatment of special waste with strongly varying consistencies. The flame center temperature in the reduction zone is controlled at about 1000 , and the hot gas temperature is controlled at about 700 . The first type of mass burning incinerator unit that is considered quite common is the rotary kiln incinerator. WebOn cutting the power to a rotary kiln, the kiln will roll back and unless a brake is applied, will continue to swing like a pendulum for ten or fifteen minutes before coming to a standstill. What If I Don't File My 1098-t, The supporting device of metallurgical and chemical rotary kiln adopts advanced spindle structure. The flue gases exiting the boiler will ultimately result in having heat, steam, power, or a combination of these utilities produced for the national grid or energy distributor, to be then used by the general public. Because traditional thrust rollers have defects in the structure, they can not meet todays needs of large-scale cement rotary kiln and are gradually replaced by hydraulic thrust rollers. The weight of the kiln body cylinder is loaded on the thrust roller through the tyre, and generates radical force and axial force acting on the thrust roller. In the fall of 2014 riverboat cruise coming to the top deck and watch sun. Fluidized bed incinerators are, as their name implies, based on the principle of fluidization of the feedstock material by suspending the solids using air (fluidizing agent). Ash drops through the grate, but many particles are carried along with the hot gases. Penelope Monkhouse, in Progress in Energy and Combustion Science, 2011. Oxygen (O2) gas is then supplied to have a combustion reaction occurring at 450C.